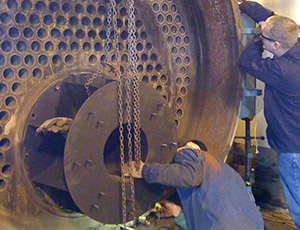

Add years to a boiler’s life and save thousands of dollars through reliable, efficient operation

According to a study conducted by the National Board of Boiler and Pressure Vessel Inspectors (NBBI), poor maintenance (typically low water safety issues) causes most boiler incidents.

If there is not a boiler room operator on staff, contact R.F. MacDonald Co. to perform regular maintenance. We offer custom maintenance options through our Equipment Maintenance Plan.

Routine Service and Maintenance – check annually or more often as needed

Fireside – Check for soot that can reduce the efficiency of your boiler tubes and furnace area. Be sure to check for water leakage and wear and tear that may require repair and indicate a larger problem.

Waterside – Check out any detectable scale that can reduce the efficiency of your boiler tubes and furnace area. Be sure to check gasket sealing surfaces for wear and tear.

Refractory – Check for cracking. Even minor cracks ca reduce boiler efficiency and allow damage to metal parts. Use a high-quality patching compound to repair, if needed.

Burners – Check dampers, nozzles, electrodes, scanners, hoses and diffusers for blockage, erosion or other damage. Replace worn or damaged parts for optimal combustion performance.

Controls – Proper water levels and operational safety and combustion devices are critical to your boiler’s performance. Carefully check gauge glass for cracks or erosion, and inspect equipment regularly.