Industrial Watertube Boilers

Cleaver-Brooks Industrial Watertube Boilers are designed with a 100 percent membrane water-cooled furnace. Each boiler system includes high-efficiency boiler and burner, heat recovery economizer and an advanced control system — all available at shortened lead times with comprehensive technical documentation.

Applications include process steam, industrial process, building heat, institutional, hospital and healthcare, power and utilities, refineries and petrochemical, pharmaceutical and pulp and paper.

![]()

Cleaver-Brooks

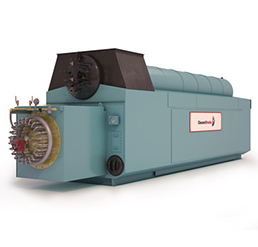

• Saturated steam

• 10,000 to 225,000 lb/hr

• Natural gas, #2 oil

• Design pressure 100 to 550 psig

• Available to less than 9 ppm NOx

• Ultra-Low CO

• Steam, temperatures to 1,050°F

• 10,000 to 500,000 lb/hr

• Natural gas, # 2 and #6 oil, alternative fuels

• Design pressure up to 1,750 psig

• Available to less than 7 ppm NOx

• Ultra-Low CO

• Steam, temperatures to 1,050°F

• 200,000 to 1,000,000 lb/hr

• Natural gas, #2 and #6 oil, alternative fuels

• Design pressure up to 2,300 psig

• Available to less than 7 ppm NOx

• Ultra-Low CO

• Steam, temperatures to 1,050°F

• 10,000 to 500,000 lb/hr

• Natural gas, #2 and #6 oil, alternative fuels

• Design pressure up to 1,750 psig

• Available to less than 7 ppm NOx

• Ultra-Low CO

• Steam, temperature to 1,050°F

• 10,000 to 500,000 lb/hr

• Natural gas, #2 and #6 oil, alternative fuels

• Design pressure up to 1,750 psig

• Available to less than 7 ppm NOx

• Ultra-Low CO

• Saturated steam

• 150,000 to 500,000 lb/hr

• Natural gas, #2 and #6 oil, propane, digester

• Design pressure up to 2,500 psig

• Available to less than 7 ppm NOx

• Ultra-Low CO