R.F. MacDonald Co. has created a comprehensive collection of white papers to assist our customers with decisions about products and services we offer. These reports are written by experts in engineering and service. Topics include technical or business benefits, tips, Q&As and recommendations.

Four Critical Factors for Longer Pump Life

Pump life span is determined by four critical factors: oil contamination, oil viscosity, air cooling, and monitoring bearing failure. Bearing and seal failure cause 90 percent of all pump failures in within the commercial and industrial markets.

Category: Process Pumps

Source: Pumps & Systems

This paper will address extending pump life and maintaining equipment in a concise, simplified manor. An ITT Goulds Pumps expert details how four (4) critical factors have the greatest on a pump’s lifespan, therefore understanding and monitoring these elements will result in effective pump operation over a maximum period of time. Ultimately, you can prevent pumping errors and maintain operations for an extended amount of time without facing an antagonizing pump failure that stalls facility operations. Read more

Keywords: Process Pumps, Pump Parts, Pump Maintenance

ITT Goulds Pumps Tests Pump Vibrations Caused by Different Style Couplings

ITT Goulds Pumps concludes the misalignment of metal couplings are less problematic than elastomeric couplings after pump vibration test.Category: Process Pumps

Source: ITT Goulds Pumps

Unacceptable pump vibrations are sometimes caused by the misalignment of the motor to the pump. Pump vibrations increases due to misalignment is dependent on the amount of misalignment and the type of coupling used.

The results and conclusions are reported of a test program that studied the effects that increasing amounts of parallel misalignment had upon pump vibration levels using different style couplings. The test setup used during the program and the test procedure followed to assure equal testing conditions for all the couplings are described. A total of nine different style couplings were tested.

One metal coupling was able to withstand a large amount of misalignment without causing a significant increase in the pump vibration level. Couplings using an elastomeric type insert tend not to increase the pump vibration levels when misaligned but do so at the cost of their useful life. Unbalance appears to be more of a problem with elastomeric couplings than with metal type couplings. Read more

Keywords: Process Pumps, Mechanical Seals, Pump Vibration

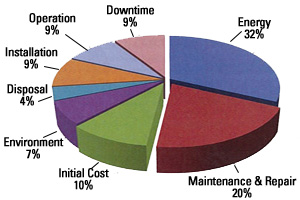

ITT Goulds Pumps Shares Total Cost of Ownership Formula

Many facilities shop for pumps based on price, but industry data shows initial costs represent only 10 percent of the Total Cost of Ownership.Category: Process Pumps

Source: ITT Goulds Pumps

This white paper shares the formula for analyzing TCO as part of purchase and design decisions, with case studies showing how five organizations used a TCO approach to yield dramatic savings.

How much does a pump cost? Ask a corporate executive or plant manager about the cost of a piece of equipment, and you’re likely to hear the purchase price. In fact, however, capital outlay is only a fraction of total operating expenses for rotating equipment. Companies that want to compete effectively should carefully measure total costs and analyze them as part of system design and equipment purchase decisions. Read more

Keywords: Process Pumps, Pump Purchasing, Pump Repair, TCO Analysis

ITT Goulds Pumps Reviews Current Pump Monitoring Capabilities

Reducing energy and improving reliability are the main drivers for intelligent pump systems, which can now use automated monitoring on all types of rotating equipment.Category: Process Pumps

Source: ITT Goulds Pumps

With rising energy costs, manufacturing plants are increasing their focus on the amount of energy spent on rotating equipment. Improperly sized or poorly performing pumps are costing companies millions of dollars unnecessarily. Unscheduled repairs and poor reliability are causing companies to lose production and spend money on maintenance costs and spare pumps that sit idle for the majority of their existence. Read more

Keywords: Process Pumps, Pump Monitoring, Pump Technology, Intelligent Pumps

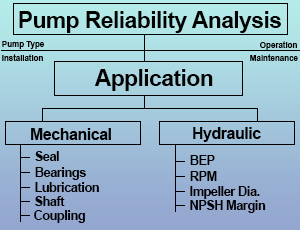

Hydraulic Selections Minimize Unscheduled Pump Maintenance

ITT Goulds Pumps coordinated a test program to quantify the effects of three hydraulic reliability factors to assist Application Engineers: operating speed, impeller diameter, and operating point.Category: Process Pumps

Source: ITT Goulds Pumps

Recently significant attention has been given to the life cycle cost of owning a pump. Major components of the cost of ownership are initial cost, installation cost, operating cost, and maintenance cost. For nearly all applications it has been found that the initial cost is a very small percentage of the life cycle cost.

In most commercial and municipal applications, the cost of power is the largest component of the cost of ownership. This validates use of efficiency as the primary selection factor. Even though the cost is high, opportunities to significantly reduce the operating cost are limited because the efficiency of pumps and motors are near their theoretical maximums. Further reductions in this cost component will come from improvements in the process.

In process plants it has been found that under many circumstances the cost of unscheduled maintenance is the most significant cost of ownership. Although numerous papers have been presented on the subject of pump reliability, that literature addresses mechanical means of improving reliability only, and does provide an objective guide for the user. There has been little published on the subject of the best hydraulic fit to optimize reliability. Read more

Keywords: Process Pumps, Pump Engineering, Hydraulic Pump Factors, Centrifugal Pumps

Hydrodynamic Seals in the Pulp & Paper Industry

The Pulp & Paper Industry has increasingly utilized hydrodynamic seals (dynamic seals) for stuffing box sealing. Learn the fundamentals of dynamic seals terminology, theory of operation, application considerations, and more.Category: Process Pumps

Source: ITT Goulds Pumps

Hydrodynamic seals have been used for over 25 years but little has been published about the design principles and the application criteria, which should be employed when this configuration is used. Early designs were used in slurry pump applications with mixed success primarily due to the lack of full understanding of the sealing capabilities of this design. Today, hydrodynamic seals are in use on slurry pumps, ANSI pumps, stock pumps, and axial flow designs among other. Read more

Keywords: Process Pumps, Mechanical Seals, Industrial Pumps, Centrifugal Pumps