EcoCAT™ Selective Catalytic Reduction (SCR)

R.F. MacDonald Co.’s EcoCAT™ Selective Catalytic Reduction (SCR) system uses a patented post-flue gas treatment capable of safety and efficiently reducing NOx emissions for a wide variety of boiler systems. SCR is one of the most effective ways of reducing NOx in a flue gas stream with reductions in excess of 95% and down to 2.5 ppm!

• The industry’s only totally integrated system

• Reduce NOx above 95%, down to 2.5 ppm

• Ammonia turns NOx into harmless nitrogen

• Flow modeling is used to optimize every system

• Applications for any fuel-fired equipment

• Total engineering & installation support

• Complete startup & testing

• Achieve a 10:1 turndown ratio

• Achieve sub 5 PPM ammonia slip

• Reduce ammonia vaporizer costs

• Reduce electrical load costs

How It Works

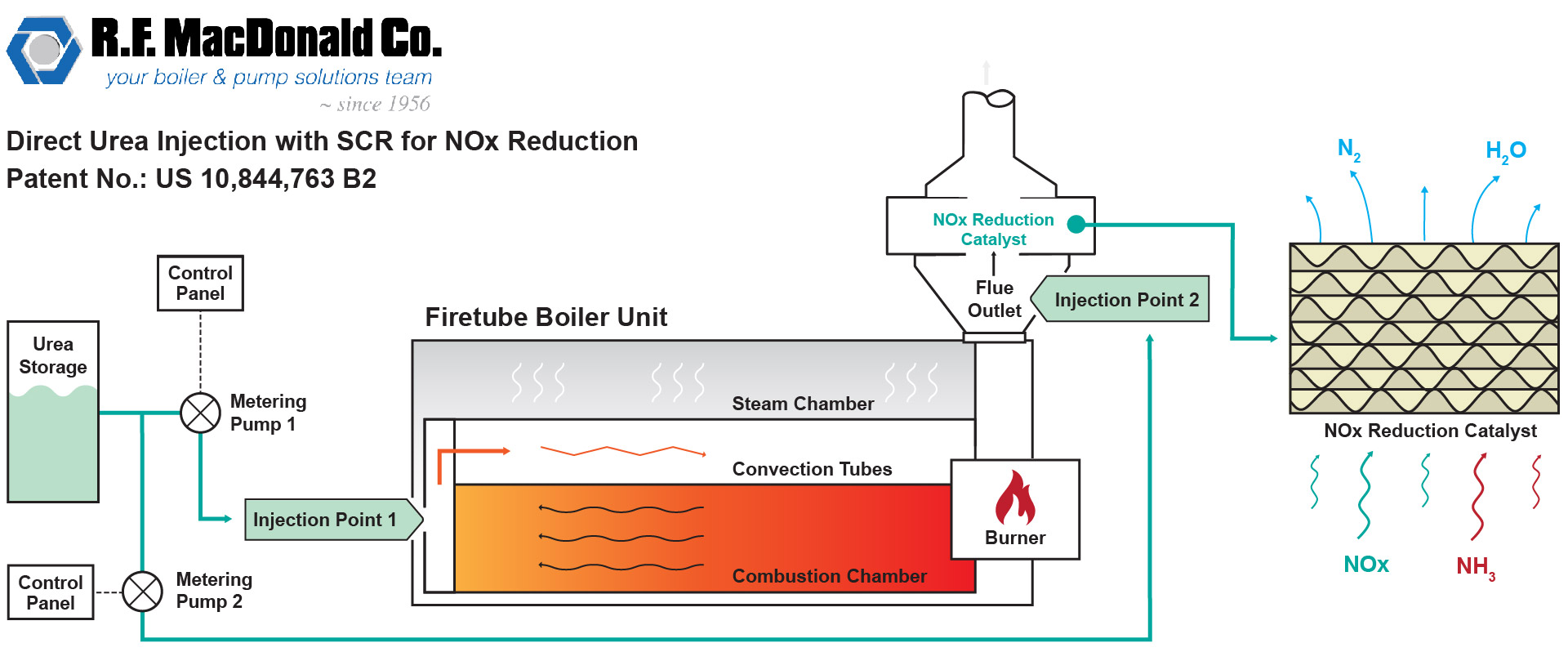

SCR uses ammonia as a reducing agent, which is introduced into the flue gas stream. This mixture then comes in contact with a catalyst, selectively transforming the NOx into harmless nitrogen and water.

With the addition of SCR, NOx emissions can be reduced down to 2.5 ppm. It’s a viable option to meet current or future environmental regulations or your company’s sustainability goal. SCR is the most effective method of NOx reduction, as it does not sacrifice boiler performance, unlike other NOx reduction technologies.

Urea Remains the Safest Ammonia NOx Reagent

Single-Source Solution with Proven Experience

R.F. MacDonald Co. is the only manufacturer that can offer a complete SCR system integrated with your boiler. That means a single-source solution with a streamlined engineering process and better value, as well as a better system with more flexibility to meet the needs of your application.

Our partners at Cleaver-Brooks manufacture every major component of the boiler system, which enables us to provide an optimal solution for your needs. We use advanced modeling software to ensure flawless design. Equipment integration allows precise adjustment to the boiler, burner and controls, resulting in the most cost-effective and efficient SCR system.

Features

- Designed specifically for your application, with both installation-ready and freestanding stacks available

- Three types of reduced agent systems are available: Anhydrous, Ammonia, Aqueous Ammonia and Urea

- Single integrated control system operates the boiler, burner and SCR

- Catalyst bed geometry is optimized and the highest quality corrugated catalyst is used with vanadium, titanium or tungsten oxides as active agents

- A custom heater recovery system allows flue gas temperatures to be optimized, resulting in the most effective reduction of NOx emissions and increased efficiency

- Completely integrated from the ammonia injection grid to the exhaust stack system, including all ladders, platforms and piping

Services

- Cold Flow Modeling (CFM) or Computational Fluid Dynamics (CFD)

- 3D Laser Scanning of boiler room/job site

- 3D Modeling Design — Integration with 3D scans

- Custom ammonia flow control unit, ammonia injection grid, and catalyst reactor housing

- Custom controls integration

- Emissions control for various fuels

Case Study

Loma Linda University Health

Boiler Installation with SCR

Loma Linda, CA

As part of the Loma Linda University Campus Transformation project, two new hospital towers were added to the medical campus. The new towers include new hospital rooms, surgical and operating rooms, nursing stations and more.

The larger packaged boilers were carefully rigged through the Central Utility Plant roof with tight clearance on all sides. Once successfully inside the building, the boilers were skillfully placed into their predetermined, limited footprint. Finally, our newly patented Direct Urea Injection with Selective Catalytic Reduction technology was installed to complete the installation process. Read more