Loma Linda University Health uses newly patented Direct Urea Injection with SCR technology to meet SCAQMD Low NOx emissions regulations

Customer Application

Loma Linda University Health includes Loma Linda University’s eight professional schools, Loma Linda University Medical Center’s six hospitals and more than 900 faculty physicians located in the Inland Empire of Southern California. Their hospitals provide quality health care to over 40,000 inpatients and 1.5 million outpatients each year. The main campus hospitals require hot water for use throughout the building and steam for sanitation, humidification and clean steam production.

Key Challenges

As part of the Loma Linda University Campus Transformation project, two new hospital towers were added to the Dennis and Carol Troesh Medical Campus. The new towers include new hospital rooms, surgical and operating rooms, chapel, healing garden, cafeterias, nursing stations and more.

As part of the Loma Linda University Campus Transformation project, two new hospital towers were added to the Dennis and Carol Troesh Medical Campus. The new towers include new hospital rooms, surgical and operating rooms, chapel, healing garden, cafeterias, nursing stations and more.

The additional facilities also required additional steam, which was provided by larger, higher-capacity boilers. R.F. MacDonald Co. was selected for this project by providing total integration services, including:

• Engineering and installation support

• Supplying boilers with our patented Direct Urea Injection with SCR technology to meet emissions regulations

• Complete startup and testing services

The R.F. MacDonald Co. Analysis & Solution

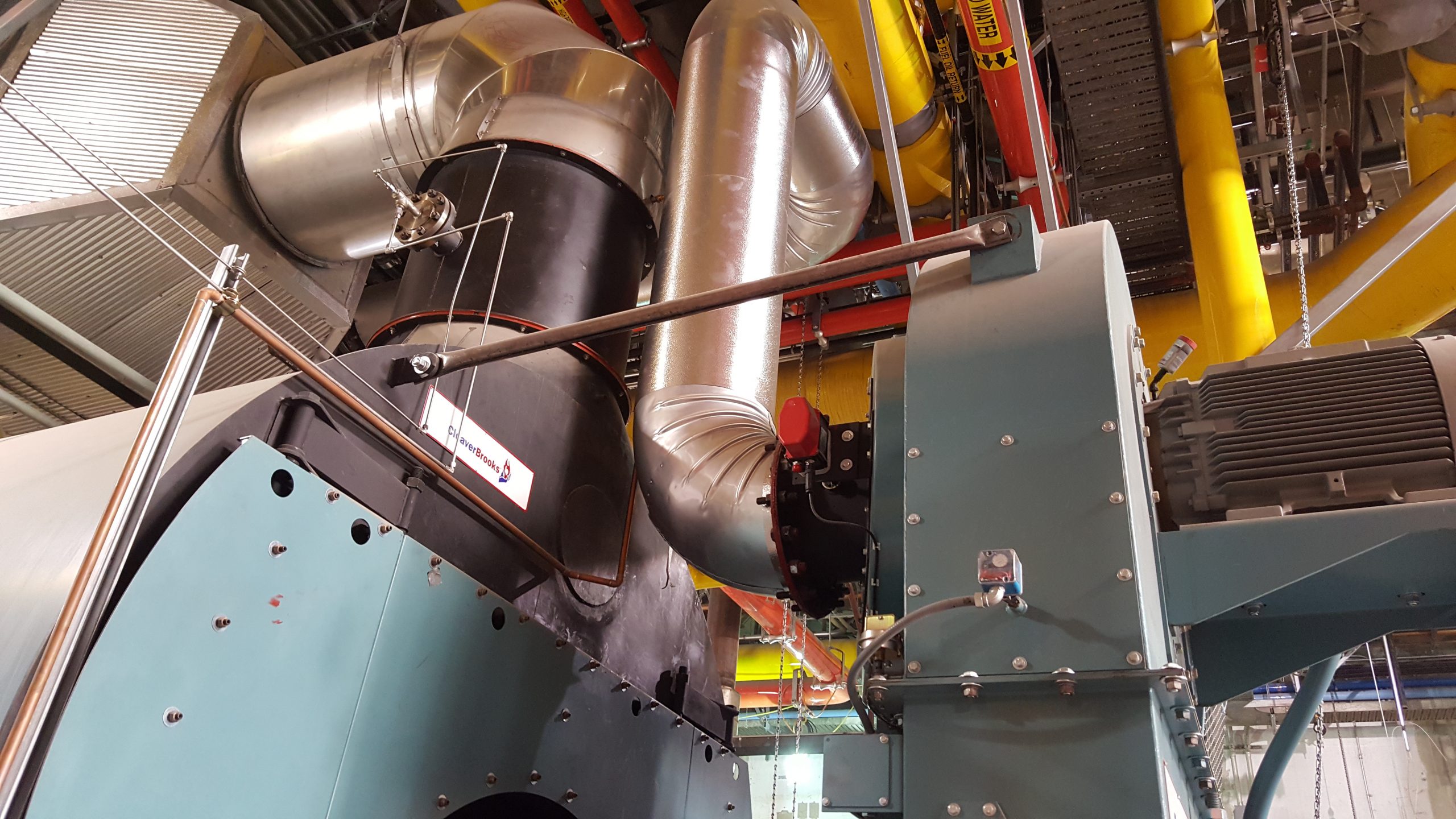

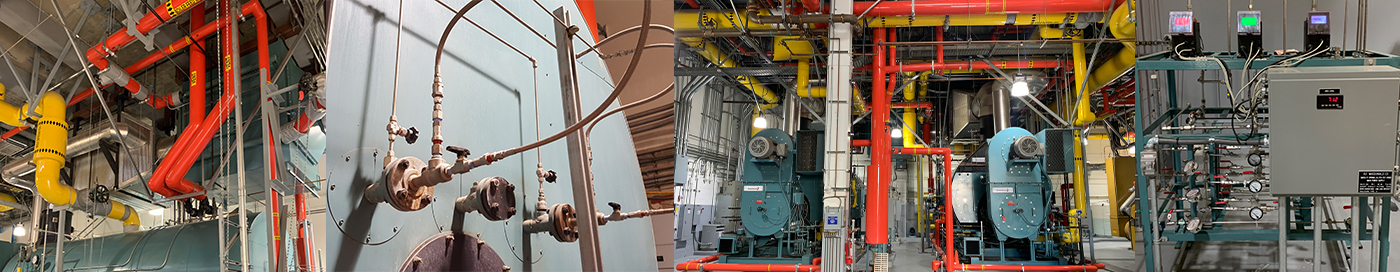

R.F. MacDonald Co. supplied three Cleaver-Brooks CBEX Elite 1,400HP firetube steam boilers to the Loma Linda University Central Utility Plant. Each boiler can produce up to 48,300 pounds of saturated steam per hour.

R.F. MacDonald Co. supplied three Cleaver-Brooks CBEX Elite 1,400HP firetube steam boilers to the Loma Linda University Central Utility Plant. Each boiler can produce up to 48,300 pounds of saturated steam per hour.

The larger packaged boilers were carefully rigged through the Central Utility Plant roof with tight clearance on all sides. Once successfully inside the building, the boilers were skillfully placed into their predetermined, limited footprint. Finally, our newly patented Direct Urea Injection with Selective Catalytic Reduction technology was installed to complete the installation process.

At approximately 58 MMBtu/hr, the larger boilers are required to meet sub 5 PPM Low NOx regulations set by the South Coast Air Quality Management District.

With several Low NOx options, LLUMC chose R.F. MacDonald Co. for two primary reasons. First, LLUH was determined to reach the highest boiler efficiency possible with a 10:1 turndown ratio, which only SCR could provide. Second, LLUH was reassured by the safety of using urea as the SCR reagent, which is a non-hazardous ammonia source.

Cleaver-Brooks ProFire XL Burner with Direct Urea Injection SCR

• Eliminates hazard of storing anhydrous/aqueous ammonia

• Achieves a 10:1 turndown ratio

• Achieves sub 5 PPM NOx emissions

• Achieves sub 5 PPM ammonia slip

• Reduces ammonia vaporizer costs

• Reduces electrical load costs

• Reduces footprint

Read about our Direct Urea Injection with SCR patent

The Loma Linda University Central Utility Plant features the latest in seismic safety and boiler efficiency, but above all, the highlight achievement is the notable sub 5 PPM NOx throughout the firing rate with sub 5 PPM ammonia slip, which is a result of our Direct Urea Injection with SCR technology.

PDF: University Medical Center Uses Direct Urea Injection with SCR