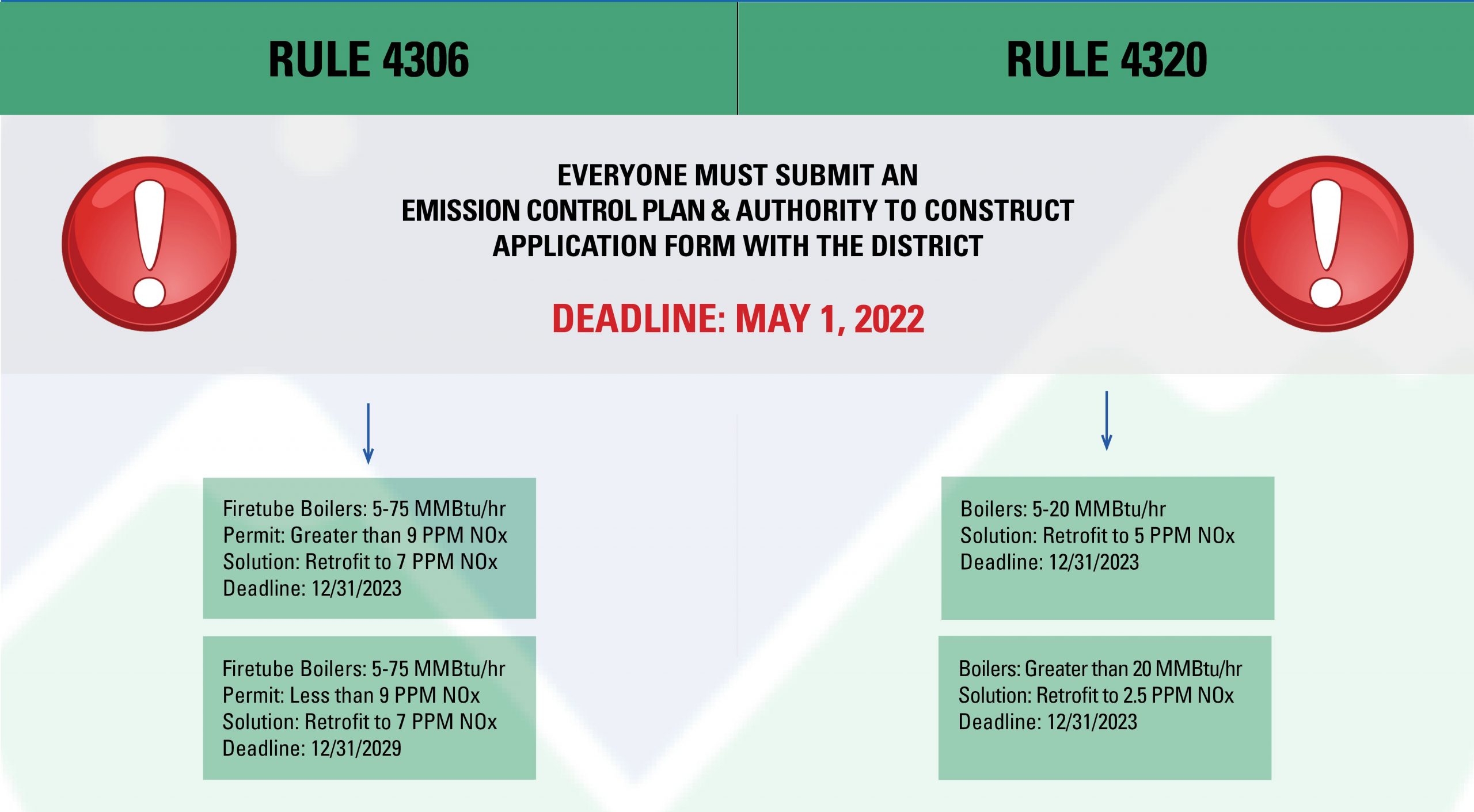

Meet the new Boiler Emissions Rules set by San Joaquin Valley Air Pollution Control District (SJVAPCD) and create a Compliance Plan to meet the 2023-29 deadlines

SJVAPCD EMISSIONS COMPLIANCE RULES

WHAT ARE YOUR OPTIONS?

Burner Retrofit

& Controls Upgrade

Selective Catalytic Reduction

Replace Your

Boiler Equipment

BURNER RETROFIT & CONTROLS UPGRADE

SUB 5 PPM NOx

NEW CLEAVER-BROOKS SBR-5 ULTRA LOW NOx BURNER

ULTRA LOW-NOx EMISSIONS – sub 5 ppm

ULTRA LOW-NOx EMISSIONS – sub 5 ppm

3-4% O2 – across a wide load range

DUAL FUEL – natural gas & no. 2 oil; fuel switchover without mechanical adjustments

MAXIMUM EFFICIENCY – provided by standardized parallel positioning

OPERATIONAL RANGE – 6:1 turndown when firing natural gas

UNIFORM FLAME – for equal heat transfer allowed by premix fuel

EASY ACCESS – air housing for internal components

INTEGRATED CONTROLS – with remote IoT monitoring capabilities

SUPPORT – locally trained reps & certified technicians

SILENT OPERATION – with an advanced combustion air fan wheel; less horsepower and less noise

ULTRA LOW-NOx/CO – achieved without a fragile surface combustion burner head, making it more safe

SELECTIVE CATALYTIC REDUCTION

SUB 5 PPM NOx • SUB 5 PPM NH3 SLIP

SCR is a post-flue gas treatment that is capable of reducing NOx emissions from a wide variety of boiler systems. SCR uses ammonia as a reducing agent, which is introduced into the flue gas stream. The mixture then comes into contact with a catalyst, selectively transforming the NOx into harmless nitrogen and water. Options are available for reducing CO emissions as well and can be integrated into a single packaged solution.

SCR WITH ANHYDROUS OR AQUEOUS AMMONIA

Project photos of SCR installations using ammonia!

• Custom ammonia flow control unit and ammonia injection grid

• Integrated control system

• Requires risk management planning

• Storage & handling oversight required per OSHA 1910.111

• Top or horizontal flow design to meet boiler room constraints

• Compatible with new or retrofit firetube and watertube boilers

• Compatible with gas turbines and reciprocating engines

SCR WITH UREA

Project photos of SCR installations using urea!

• R.F. MacDonald Co. patented design does not require vaporizer

• Eliminates hazards of storing ammonia

• Does not require a risk management plan

• Reduces electrical load costs and footprint

• Top or horizontal flow design to meet boiler room constraints

• Compatible with new or retrofit firetube and watertube boilers

• Compatible with gas turbines and reciprocating engines

ENGINEERING SERVICES

Our highly experienced draftsmen produce AutoCAD and Solid Works drawings, including general arrangements, foundation loading, piping configurations, power distribution, electrical wiring, interface/termination and logic flow in accordance with your specifications

• Cold Flow Modeling (CFM) or Computational Fluid Dynamics (CFD)

• 3D laser scanning and modeling design of boiler room or job site

• Custom emissions controls integrated for various fuel types

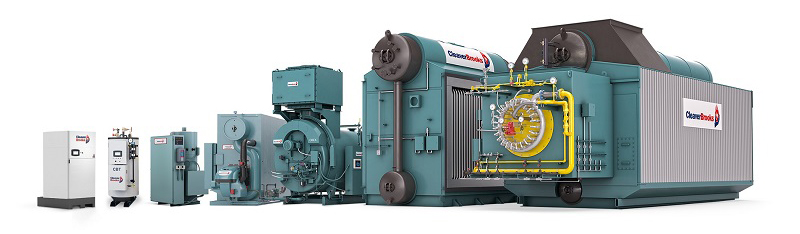

REPLACE YOUR EQUIPMENT

Contact your local R.F. MacDonald Co. representative to discuss options for your facility

PDF Download: SJVAPCD Rules 4306 & 4320 Clear the Air Brochure