R.F. MacDonald Co. has created a comprehensive collection of white papers to assist our customers with decisions about products and services we offer. These reports are written by experts in engineering and service. Topics include technical or business benefits, tips, Q&As and recommendations.

Understanding the Different Names and Terminology for Steam

Many different terms are used to describe steam in various applications. This inconsistency can result in improper reporting and work order errors.

Category: Steam Boilers

Source: Cleaver-Brooks

This paper will address utility steam applications. Any steam application outside of utility steam should follow company policies and regulations of any governing agency or organization. 1. Utility Steam (Live Steam, Plant Steam): Utility steam is sometimes called “live steam” or “plant steam.” It is steam produced from the boiler operation using softened water, reverse osmosis, or water otherwise treated for the boiler.Utility steam makes up the majority of the steam consumed by industrial process applications. Utility steam is a dry and invisible fluid that contains both sensible and latent energy, which can be provided to the process as saturated or superheated steam. Read more

Keywords: Steam Boilers, Utility Boilers

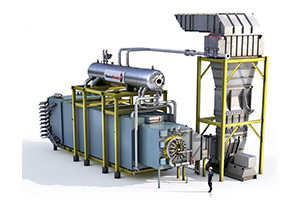

Engineering the First Steam-Ready Industrial Watertube Boiler

The primary benefit of a steam-ready system is the shortened design-to-installation time, allowing customers to engineer a project in advance.

Category: Steam Boilers

Source: Cleaver-Brooks

The pace of business today dictates that manufacturers bring products to market faster through the continuous streamlining of product innovation, product development and engineering processes. A few years ago, one leading manufacturer of industrial watertube (IWT) boiler systems committed itself to accomplishing this goal. The company took its past experience and proven design and combined it with new technologies to develop a steam-ready integrated, industrial watertube boiler system that reduces the overall project schedule by 30 percent. Read more

Keywords: Steam Boilers, Steam-Ready Boilers, Industrial Watertube Boilers

Forced-Circulation Steam Generators for SAGD Applications

Steam-Assisted Gravity Drainage, better known as SAGD, is considered to be the most viable and environmentally safe recovery technology for extracting heavy oil.

Category: Steam Generators

Source: Cleaver-Brooks

In the SAGD process, one well is drilled above the bitumen deposit and a second one below the deposit. Bitumen is used to make asphalt. The upper well is supplied with high-pressure steam, and the lower well collects the heated oil or bitumen that flows out, along with any water from the condensation of injected steam. The bitumen and water are pumped out and travel to a tank, where the two elements are separated. This “produced water” is then cleaned and returns to the boiler, where it is converted into steam and injected back into the ground. Read more

Keywords: Steam Boilers, Steam Generators, Oil Industry