Boiler Equipment Maintenance Plans

We offer a customizable Boiler Equipment Maintenance Plan to maintain optimum performance, improve system stability, extend equipment life, and minimize risk of a boiler system failure. By participating in the contracted service, your equipment will receive the necessary assessments, testing, and maintenance to fully support the routine and essential inspections. Ultimately, these services will enhance equipment safety, efficiency, and performance. At the end of the annual maintenance, the boiler will be closed and fitted with new high-quality gaskets. All findings will be properly documented.

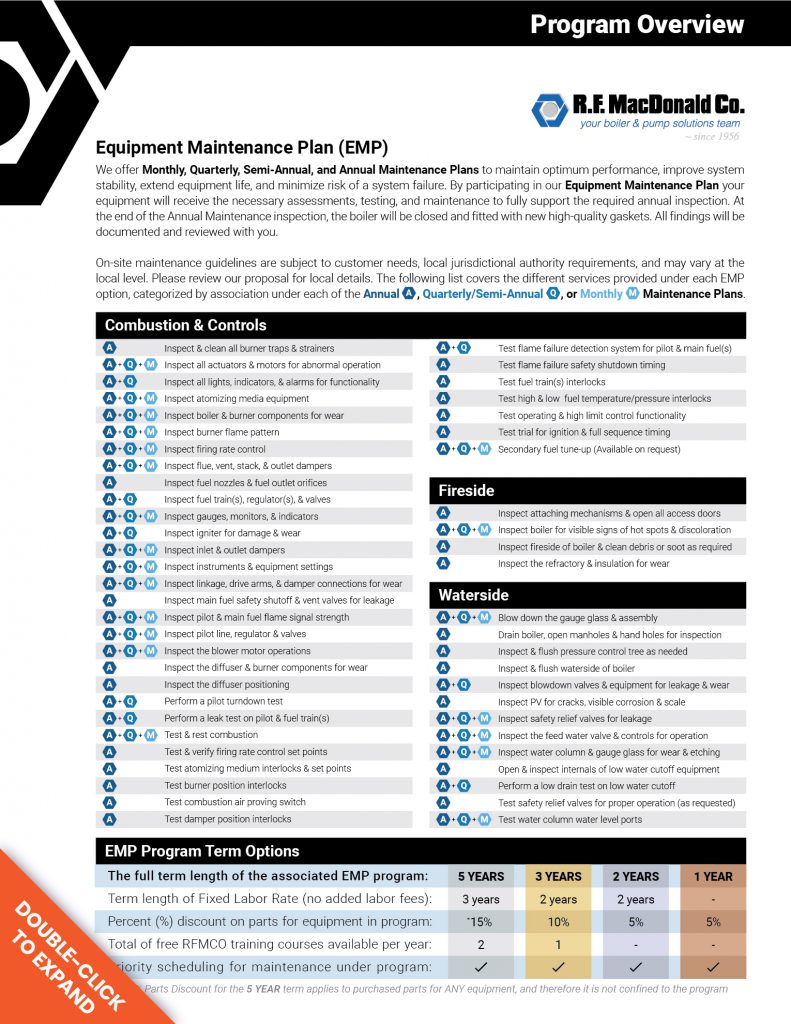

Customize Your Maintenance Visit Schedule

- To accommodate your operational needs and availability, you can customize the frequency of on-site visits to be Annual, Semi-Annual, Quarterly, or Monthly. Each option entails different inspections and services associated with each visit, see what’s included in each plan below.

- MONTHLY

The Maximum Coverage option where preventive maintenance will be performed every month. The inspections and tests listed below will be completed eight (8) times a year in addition to one (1) Annual Maintenance visit and three (3) Quarterly Maintenance visits.

Combustion and Controls- Inspect all actuators & motors for abnormal operation

- Inspect atomizing media equipment

- Inspect boiler & burner components for wear

- Inspect burner flame pattern

- Inspect firing rate control

- Inspect flue, vent, stack, & outlet dampers

- Inspect fuel train(s), regulator(s), & valves

- Inspect gauges, monitors, & indicators

- Inspect inlet & outlet dampers

- Inspect instruments & equipment settings

- Inspect linkage, drive arms, & damper connections for wear

- Inspect pilot & main fuel flame signal strength

- Inspect pilot line, regulators, & valves

- Inspect the blower motor operations

- Test & reset combustion

- (Add-on) Secondary fuel tune-up

Fireside

- Inspect boiler for visible signs of hot spots & discoloration

Waterside

- Blow down the gauge glass assembly

- Inspect the safety relief valves for leakage

- Inspect the feed water valve & controls for operation

- Inspect water column & gauge glass for wear & etching

- Test water column water level ports

- QUARTERLY

The Principal Coverage option where preventive maintenance will be performed on a quarterly basis. The inspections and tests listed below will be completed three (3) times a year in addition to one (1) Annual Maintenance visit. The same features are also available with the Semi-Annual Maintenance option, but with less scheduled visits.

Combustion and Controls- Inspect all actuators & motors for abnormal operation

- Inspect all lights, indicators, & alarms for functionality

- Inspect atomizing media equipment

- Inspect boiler & burner components for wear

- Inspect burner flame pattern

- Inspect firing rate control

- Inspect flue, vent, stack, & outlet dampers

- Inspect fuel train(s), regulator(s), & valves

- Inspect gauges, monitors, & indicators

- Inspect igniter for damage & wear

- Inspect inlet & outlet dampers

- Inspect instruments & equipment settings

- Inspect linkage, drive arms, & damper connections for wear

- Inspect pilot & main fuel flame signal strength

- Inspect pilot line, regulators, & valves

- Inspect the blower motor operations

- Perform a pilot turndown test

- Perform leak test on pilot & fuel train(s)

- Test & reset combustion

- Test flame failure detection system for pilot & main fuel(s)

- (Add-on) Secondary fuel tune-up

Fireside

- Inspect boiler for visible signs of hot spots & discoloration

Waterside

- Blow down the gauge glass assembly

- Inspect blowdown valves & equipment for leakage & wear

- Inspect the safety relief valves for leakage

- Inspect the feed water valve & controls for operation

- Inspect water column & gauge glass for wear & etching

- Test water column water level ports

- Perform a slow drain test on low water cutoff

- SEMI-ANNUAL

The Adjusted Principal Coverage option where preventive maintenance will be performed on a semi-annual basis. The inspections and tests listed below will be completed two (2) times a year. The same features are also available with the Quarterly Maintenance option, but with more scheduled visits.

Combustion and Controls- Inspect all actuators & motors for abnormal operation

- Inspect all lights, indicators, & alarms for functionality

- Inspect atomizing media equipment

- Inspect boiler & burner components for wear

- Inspect burner flame pattern

- Inspect firing rate control

- Inspect flue, vent, stack, & outlet dampers

- Inspect fuel train(s), regulator(s), & valves

- Inspect gauges, monitors, & indicators

- Inspect igniter for damage & wear

- Inspect inlet & outlet dampers

- Inspect instruments & equipment settings

- Inspect linkage, drive arms, & damper connections for wear

- Inspect pilot & main fuel flame signal strength

- Inspect pilot line, regulators, & valves

- Inspect the blower motor operations

- Perform a pilot turndown test

- Perform leak test on pilot & fuel train(s)

- Test & reset combustion

- Test flame failure detection system for pilot & main fuel(s)

- (Add-on) Secondary fuel tune-up

Fireside

- Inspect boiler for visible signs of hot spots & discoloration

Waterside

- Blow down the gauge glass assembly

- Inspect blowdown valves & equipment for leakage & wear

- Inspect the safety relief valves for leakage

- Inspect the feed water valve & controls for operation

- Inspect water column & gauge glass for wear & etching

- Test water column water level ports

- Perform a slow drain test on low water cutoff

- ANNUAL

The Core Coverage option where preventive maintenance will be performed on a semi-annual basis. The inspections and tests listed below will be completed once a year.

Combustion and Controls- Inspect all actuators & motors for abnormal operation

- Inspect all lights, indicators, & alarms for functionality

- Inspect & clean all burner traps & strainers

- Inspect atomizing media equipment

- Inspect boiler & burner components for wear Inspect burner flame pattern

- Inspect firing rate control

- Inspect flue, vent, stack, & outlet dampers

- Inspect fuel nozzles & fuel outlet orifices

- Inspect fuel train(s), regulator(s), & valves

- Inspect diffuser positioning

- Perform a pilot turndown test

- Perform leak test on pilot & fuel train(s)

- Test & reset combustion

- Test & verify firing rate control set points

- Test flame failure safety shutdown timing

- Test fuel train(s) interlocks

- Test high & low fuel temperature/pressure interlocks

- Inspect gauges, monitors, & indicators

- Inspect igniter for damage & wear

- Inspect inlet & outlet dampers

- Inspect instruments & equipment settings

- Inspect linkage, drive arms, & damper connections for wear

- Inspect main fuel safety shutoff & vent valves for leakage

- Inspect pilot & main fuel flame signal strength

- Inspect pilot line, regulators, & valves

- Inspect the blower motor operation

- Inspect the diffuser & burner components for ear

- Test atomizing medium interlocks & set points

- Test burner position interlocks

- Test combustion air proving switch

- Test damper position interlocks

- Test flame failure detection system for pilot & main fuel(s)

- Test operating & high limit control functionality

- Test trial for ignitions & full sequence timing

- (Add-on) Secondary fuel tune-up

Fireside

- Inspect boiler for visible signs of hot spots & discoloration

- Inspect attaching mechanisms & open all access doors

- Inspect fireside of boiler & clean debris or soot as required

- Inspect the refractory & insulation for wear

Waterside

- Drain boiler, open manholes & handholes for inspection

- Inspect & flush waterside of boiler

- Inspect PV for cracks, visible corrosion & scale

- Inspect the feed water valve & controls for operation

- Open & inspect internals of low water cutoff equipment

- Test safety relief valves for proper operation (as requested) Blow down the gauge glass assembly

- Inspect & flush pressure control tree as needed

- Inspect blowdown valves & equipment for leakage & wear

- Inspect the safety relief valves for leakage

- Inspect water column & gauge glass for wear & etching

- Perform a slow drain test on low water cutoff

- Test water column water level ports Terms of Plan Membership

Membership Term Options

In addition to offering customizable options for the frequency of maintenance services, we also provide the ability to select the corresponding term duration, indicating the length of the membership contract. We’ve divided these options into four (4) tiers, each one coming with complimentary benefits added to the extended length.

5 YEARS

Recurring services and inspections for five years. Term benefits include:

- Fixed labor rate for three (3) years

- 15% discount on parts for any equipment

- Two (2) free training classes at a local seminar

- Priority scheduling benefits

- (Add-on) Onsite Pump Training

3 YEARS

Recurring services and inspections for three years. Term benefits include:

- Fixed labor rate for two (2) years

- 10% discount on parts for contracted equipment

- One (1) free training classes at a local seminar

- Priority scheduling benefits

- (Add-on) Onsite Pump Training

2 YEARS

Recurring services and inspections for two years. Term benefits include:

- Fixed labor rate for two (2) years

- 5% discount on parts for contracted equipment

- Priority scheduling benefits

- (Add-on) Onsite Pump Training

1 YEAR

Selected services and inspections for one year. Term benefits include:

- 5% discount on parts for contracted equipment

- Priority scheduling benefits

- (Add-on) Onsite Pump Training

Free Boiler Training

5 Year EMP = Two (2) free training classes at a local seminar

3 Year EMP = One (1) free training class at a local seminar

Why Should You Invest?

Routine Boiler and Pressure Vessel inspections are required by local jurisdictions. Typically, these critical inspections are required annually, but in some rare cases, they can be required bi-annually. The inspection frequency is determined by local laws and regulations. As such, Boiler and Pressure Vessel inspections are unavoidable and will result in a boiler and/or boiler system to be temporarily taken offline. The specific details involved to perform an annual inspection can be overwhelming for companies that do not have the resources to stay current with changing compliance regulations. As a result, it is beneficial and very common for companies to engage in knowledgeable technical resources who can easily navigate the inspection process. Outsourcing this responsibility to trained technicians can facilitate an expedient and successful approval by the local jurisdiction while enhancing your preventive maintenance objectives.

Under the Equipment Maintenance Plan, you can—

- Improve operational stability

- Improve burner combustion efficiency

- Improve boiler heat transfer efficiency

- Enhance safety and issue identification

- Reduce long-term repair cost

- Discounted parts quotes where needed

- Fixed labor erase inconvenience service fees

- Reduce annual inspection difficulties

- Priority access to technical expertise & service support

- Priority access to R.F. MacDonald Co. parts inventory

- Single-source responsibility for boiler system support

- Extend equipment life

Maintaining Your Equipment

Whether or not you choose to utilize our preventive maintenance program, we highly recommend that you take steps to ensure that your boiler equipment is protected. Additionally, we offer accredited training courses on boiler operations and mechanics, visit R.F. MacDonald Co. Training for more information. Below are some valuable tips to follow when being proactive on the condition of your boiler application.

Controls

Proper water levels, operating pressures, and control devices are critical to your boiler system’s performance. Carefully check gauge glass for cracks or erosion and inspect the float and switches. Check the operation of all limit switches and sequences of operation timing.

Burners

Remove, check and clean dampers, nozzles, electrodes, scanners, hoses, compressors, filters, diffusers, etc. for blockage and/or damage.

Refractory

Check for cracking. Unrepaired, even mirror cracks can reduce boiler efficiency and allow warping and damage to occur on vital metal surfaces.

Fireside

Cleaning out any detectable soot can reduce the efficiency of your boiler tubes, tube sheets, and furnace area. Replace fireside gaskets when closing the boiler.

Waterside

Drain, open and flush the entire waterside of the boiler. Remove all low water controls to clean and inspect piping. Flush makeup and/or feed water pump strainers and water column float chambers. Drain expansion tanks and remove all plugs in control piping. Inspect and re-install controls. Inspect for damage due to waterside leakage around handholes and manholes, gauge glass assemblies and other wet surfaces. Check gaskets for wear and tear.