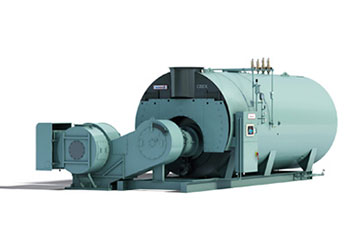

CB Boiler Model CBEX Elite (1,300 – 2,200HP)

The new Cleaver-Brooks CBEX Elite flagship firetube steam boiler featuring EX technology is a completely integrated boiler, burner, control, and heat recovery system. Every core component has been designed and built by Cleaver-Brooks to work together, resulting in the most efficient and lowest-emissions firetube system ever built.

The new Cleaver-Brooks CBEX Elite flagship firetube steam boiler featuring EX technology is a completely integrated boiler, burner, control, and heat recovery system. Every core component has been designed and built by Cleaver-Brooks to work together, resulting in the most efficient and lowest-emissions firetube system ever built.

- 1,300 to 2,200 HP

- Natural gas, #2 light Oil or combination

- 50 to 250+ psig steam

- Available to <9 ppm NOx

- Wetback design

Product Overview

Using finite element analysis, the revolutionary system was designed to optimize every component of the boiler, including the burner, the furnace, and the tubes, and provide uniquely balanced temperatures and heat loads.

Extended heat transfer tubing only found in EX systems uses Computational Fluid Dynamics (CFD) calculations to optimize the geometry of the tube and increase heat transfer by 85%. The result of the advanced heat transfer design is higher efficiency and lower emissions in a 15% smaller footprint.

The CBEX Elite is the only boiler package in the world to maintain 3% oxygen across the full operating range with 30 ppm NOx performance while firing natural gas.

Integration of the core components is the key to the CBEX systems. The superior Hawk control allows the boiler to run at the absolute maximum efficiency. Reduce fuel use with the stack economizer by recovering waste heat from flue gases and using it to preheat boiler feedwater. The LevelMaster low-water cutoff and pump control is the safest control available.

Features:

- Best fuel efficiency of any firetube ever built

- Completely integrated boiler, burner, control, and heat recovery system

- Maintains a small footprint in large capacities

- Affordable alternative to industrial watertube boilers

- Minimum excess air across the operating range

- Meets 9 ppm NOx emissions requirements without Selective Catalytic • Reduction (SCR)

- Wetback design

Solutions:

- Lower Fuel Cost

- Lower Emissions

Applications:

- Process Steam

- Industrial Process

- Building Heat

- Sterilization

- Humidification

- Hospital and Healthcare

- Power and Utilities

- Refineries and Petrochemical