Selective Catalytic Reduction (SCR)

Installing an SCR system helps companies solve low NOx requirements set by the California Air Resources Board – as well as into the future with efficient performance, ease of use and long equipment life times. The case studies here examine industrial boiler applications and their key challenges.

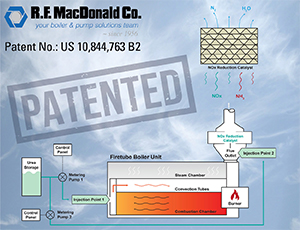

R.F. MacDonald Co. Urea Patent

Direct Urea Injection with SCR for NOx Reduction

Modesto, CA

R.F. MacDonald Co. has patented a process for direct injection of urea in flue gas streams on boilers; urea is regarded as the safest reagent for use in the SCR process

On Tuesday, Nov. 24, 2020 the U.S. Patent and Trademark Office issued the safest and simplest NOx-reduction process patent for packaged boilers. The patent was granted to R.F. MacDonald Co. for inventing a “process for direct urea injection with selective catalytic reduction (SCR) for NOx reduction in hot gas streams and related systems and assemblies.”

SCR requires the use and storage of ammonia-based reagents, which range from high risk to low risk. The R.F. MacDonald Co. patent specifies urea, which is the lowest risk ammonia-based reagent. The only health hazard associated with urea is “possible irritation” as indicated by the Hazardous Materials Identification System (HMIS). The urea solution is identical to Diesel Exhaust Fluid (DEF), which is sold worldwide in automotive retail stores for use in diesel motor vehicles. Read more

Teasdale Foods

70,000pph, 5ppm NOx BPS Steam Plant

Atwater, CA

New steam plant with SCR technology provides overall processing efficiency.

With roots traced back to the 1930s, Teasdale Quality Foods has been providing high quality, delicious products for more than 70 years. Located in the heart of California, they are recognized as a leader and innovator providing retail, food service, and industrial customers with a full line of Hominy and Dry Soak Beans.

Over time, their steam plant slowly deteriorated until they were running their entire operation on a single boiler with no economizer. As a result, the production process became inefficient and consumed high quantities of excess air. After entering negotiations with a private equity firm to sell their company, Teasdale Quality Foods set a goal to upgrade their boiler to meet current and future air quality regulations, but was unsure where to begin. Read more

Keywords: boiler feedwater pumps, SCR system, steam boiler plant, boiler case studies, CB Nebraska boiler, boiler projects, food processing boilers, SJVAPCD requirements, Haldor-Topsoe catalyst

Ingredion (formerly Corn Products)

Install SCR System

Stockton, CA

Supply and install an SCR system to operate with existing HRSG.

Ingredion is a world-leading ingredient solutions provider; turning corn, tapioca, wheat, potatoes, and other raw materials into a myriad of ingredients for the food, beverage, brewing, and pharmaceutical industries as well as numerous industrial sectors. With more than 10,000 employees worldwide, Ingredion serves customers in more than 60 diverse markets while remaining committed to supplying their customers with innovative ingredient solutions that are on-trend and in demand.

Ingredion’s Stockton processing plant is equipped with a gas turbine and cogen Heat Recovery Steam Generator (HRSG) that recaptures exhaust to generate electricity for the plant. Ingredion was interested in a new SCR system to reduce their NOx emissions from this process to below 9 ppm. Having used R.F. MacDonald Co. as a reliable provider of knowledge and service for their NOx-related issues in the past, Ingredion turned to R.F. MacDonald Co. once again to assist with their current SCR needs. Read more

Keywords: SCR system, boiler case studies, boiler projects, Haldor-Topsoe catalyst, SJVAPCD requirements, food processing boilers

Leprino Foods Lemoore West

Install SCR System

Lemoore, CA

New boiler using selective catalytic reduction (SCR) to meet requirements.

Leprino Foods, is a world leader in premium-quality cheese manufacturing and the largest U.S. exporter of whey products. Leprino mozzarella cheese, cheese blends, and pizza cheese are made especially for pizzeria and foodservice operators, frozen food manufacturers and private label cheese packagers.

The Lemoore facility was planning a large expansion to a 500,000 sq. ft. cheese-making and whey-processing facility that is one of the world’s largest cheese plants today. This expanded plant would require additional steam for processing. R.F. MacDonald Co. worked in conjunction with the facility engineers to deliver and install a boiler system that would meet the plant’s production demands as well as the new Ultra-Low NOx requirements of the San Joaquin Valley Air Pollution Control district. Read more

Keywords: SJVAPCD requirements, boiler case studies, boiler projects, food processing boilers, SCR system, boiler maintenance