Replacing old high-pressure pumps with a cost-effective pumping system using Grundfos hydro HP pumps

By: Michael Salvato, Industry Market Development Manager, Grundfos USA

WASH AND CLEAN WHITE PAPER

THE NEW TECHNOLOGY THAT CAN OUTSAVE & OUTSMART TRADITIONAL TECHNOLOGY

Grundfos Hydro HP Brochure (PDF)

Grundfos Hydro HP Whitepaper (PDF)

Introduction

High-pressure pumping is a requirement for wash and clean for food processing. While traditional technologies require significant and costly maintenance, today’s manufacturers and processors need updated technology that delivers high energy efficiency, reliable durability, and simple, low-cost maintenance with a low total life-cycle cost.

Time and cost-effective wash and clean systems that accommodate high and low-flow demands are instrumental for food and beverage producers to ensure product integrity, minimize downtime and maintain brand confidence. Designed with these key areas in mind, a packaged pumping solution for wash and clean also has potential application and benefits beyond the food processing space. For pulp and paper manufacturers, process and energy efficiency is directly related to cost savings. Shower wash systems must operate at optimal washing efficiency with minimal maintenance to improve production while minimizing energy consumption. The high-pressure and high-temperature demands of boiler feed applications require pumping systems that demonstrate remarkable durability and energy efficiency, especially in the context of wash and clean within food processing.

In this paper we will look at how the Hydro HP engineered systems have been designed to address the specific pain points and challenges of today’s industries.

Purpose

The purpose of this paper is to present some of the features a fully integrated pumping system can offer clean and wash applications. It will explain the benefits of using integrated VFD, the energy efficiency and maintenance benefits of vertical inline multistage pumps, SCADA system integration, and OPEX cost savings of the Hydro HP pump system.

A Complete Pumping System

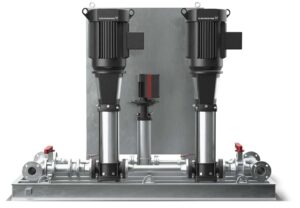

The approach that meets the needs of food processors while offering a compact system footprint is the Grundfos Hydro HP, a multistage inline pump system that incorporates a low horsepower jockey/pressure-maintenance pump with up to five high-pressure pump tandems in a booster set to provide steady pressure from 5 gpm to 500 gpm. These simple, high-efficiency pumping systems use easy-to-maintain, energy efficient and proven CR vertical multistage pumps to provide consistent performance for high pressure applications. Additionally, the Hydro HP is built to withstand the harsh environments sometimes encountered in processing plants.

In today’s challenging environment, the importance of integrated control and remote management capabilities cannot be overstated. To optimize system performance and energy efficiency, premium efficient motors are coupled with motor integrated VFD (MLE motor) or panel mounted VFD technology, all controlled by a CU 352 master controller that seamlessly interfaces with plant SCADA systems to automatically monitor and control flow for up to six pumps or tandem pumps. The result is an automated system that runs on the minimum horsepower required at all times for maximum energy savings while meeting the variable demands of the wash and clean system.

Hydro HP Technology in Detail

CR/CRN Pumps

At the heart of the Hydro HP system are the CR/CRN* pumps. CR pumps are advanced in their design and efficiency but simple to maintain with engineered wear part kits.

If low-flow demands are part of the operational demand for the system, a small, 10 hp CRNE 1-23 pump is provided to efficiently keep the piping system pressurized and to provide low-flow demands of 5-15 gpm. This low-flow requirement is commonly needed for clean and wash applications where spot cleaning might be required during production. And, this jockey pump eliminates the need for a recirculation/bleed line, a common requirement for systems using pitot tube and positive displacement (PD) pumps.

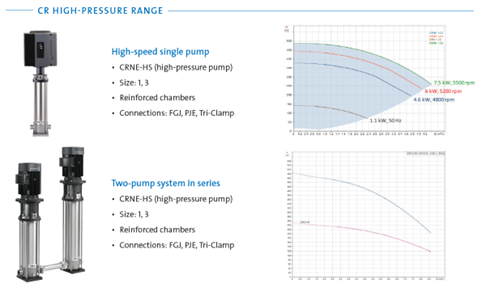

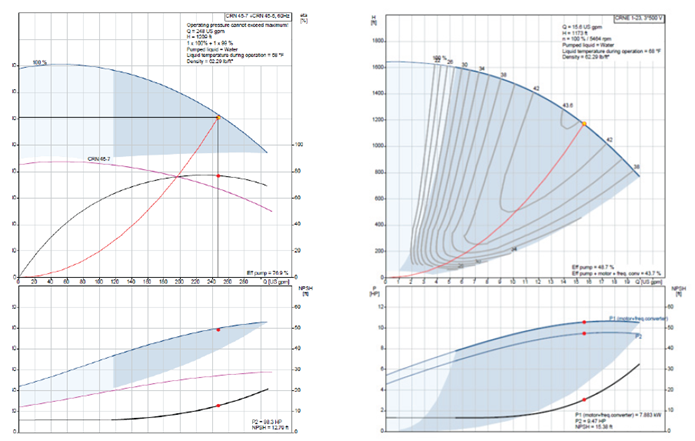

For the higher system flow demands, a high-pressure, tandem series pair of CR 32 or CR 45 pumps is used. For systems with even greater flow demands, additional high-pressure tandem pairs of pumps can be added in parallel to increase the flow capability of the Hydro HP system. Each tandem pair is controlled as a single pump, with a maximum of six sets of tandem pairs and/or a jockey pump able to be controlled per CU 352 controller.

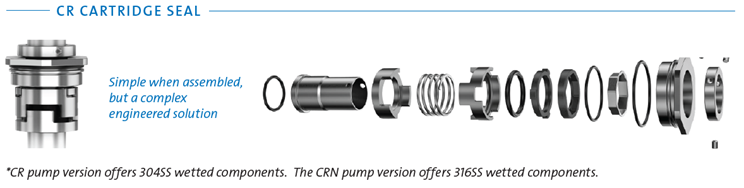

All CR pumps feature an all-in-one cartridge seal, Grundfos engineered and produced for fast and easy service while providing for superior tolerance to dry running conditions. By simply removing the shaft/spacer coupling, the cartridge seal can be replaced on site in 20-30 minutes, without removing the pump motor.

Hydro HP Technology in Detail

VFD Controls on the Hydro HP To provide a constant system pressure at a wide range of system flows, the Hydro HP relies on VFD controls. The VFD controls the speed of the motor to provide the needed system pressure while using the minimum amount of horsepower for energy efficiency. In addition to these benefits, VFD control reduces pressure surging, keeping stress on the distribution piping system to a minimum.

If a jockey pump is needed for the system, the VFD for this 10 hp pump will always be the MLE, the Grundfos VFD integrated motor.

Depending on the maximum pressure and flow requirement, the main high-pressure tandem pair of pumps will rely on either an MLE motor or a Grundfos panel-mounted CUE VFD. On the standard Hydro HP system, the VFD controls the speed of the feed pump, while the second pump in the tandem, the boost pump, runs at constant speed. This control scheme provides excellent system pressure control and cost efficiency. The MLE motor is available up to 30 hp, a VFD larger than 30 hp will be a panel mounted CUE VFD. Grundfos also offers VFD control on both feed and boost pumps to further optimize energy efficiency for a nominal increase in capital cost.

Regardless of whether the VFD is an MLE motor or CUE, the Grundfos factory-loaded firmware includes the pump curve for the pumping end. What this means is that the VFD knows where the pump will run at best efficiency. Grundfos VFDs understand Grundfos pumps, so plant maintenance engineers will not need to trim the system for optimized operational efficiency.

The VFD allows us to turn down the pump, so it can efficiently provide low-flow demands at system pressures over a wide

operating range.

Hydro HP Technology in Detail

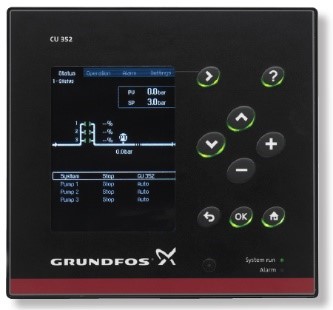

Pump Station Control – The CU 352

The brains of the Hydro HP is the field-proven, CU 352 multi-pump controller. The color HMI on the CU 352 is user-friendly, and easy to read and navigate.

The brains of the Hydro HP is the field-proven, CU 352 multi-pump controller. The color HMI on the CU 352 is user-friendly, and easy to read and navigate.

The main purpose of the CU 352 on the Hydro HP is to control the sequence of operation of the pumps (cascade control) to provide constant system pressure while using the pumps to their best efficiency, all while keeping the operator fully informed of the system status at all times.

Before the Hydro HP system ships, the CU 352 controller is loaded with the specific curve for the pumps under its control. Like the data in the VFD firmware, this allows the CU 352 to control pump sequencing using the pumps to their best advantage with no additional programming required by plant maintenance engineers.

Additionally, the CU 352 HMI provides detailed information on:

• The system status (dynamic pressure and flow)

• Pump running status and run hours

• Alarm conditions and alarm reports

• Time stamps for any such alarm event

The CU 352 has battery backup, so user settings and the alarm log is not lost in the event of power outages. And all of this data can be integrated into the plant SCADA system.

Plant SCADA Interfacing

For SCADA monitoring and control of the pump system, the Grundfos fieldbus concept provides the solution. Specifically, the CU 352 can be equipped with a Communication Interface Module (CIM) card that facilitates the easy integration of over 30 data points for monitoring or control through the plant SCADA system. With CIM card integration, almost every function at the HMI is available through SCADA.

For SCADA monitoring and control of the pump system, the Grundfos fieldbus concept provides the solution. Specifically, the CU 352 can be equipped with a Communication Interface Module (CIM) card that facilitates the easy integration of over 30 data points for monitoring or control through the plant SCADA system. With CIM card integration, almost every function at the HMI is available through SCADA.

The CIM card can be specified for a number of commonly used protocol, including: BACnet MS/TP, BACnet IP, Profinet I/O, Profibus DP, Modbus TCP, RTU, Lonworks, and EtherNet/IP. The CIM card can be installed into the CU 352 at the factory or easily retrofitted in the field. The 500 series card for Modbus is pictured.

OPEX and Life-Cycle Costs

Wear Kits and Recommended Service Intervals With all of the built-in efficiencies of the Hydro HP system, the ROI on the lifecycle OPEX costs in comparison to currently used pitot tube or positive displacement pump systems is expected to be within 5 years of installation.

The simple design of CR pumps and the engineered wear part/service kits will allow the Hydro HP to be serviced on site easily and safely by most plant maintenance engineers.

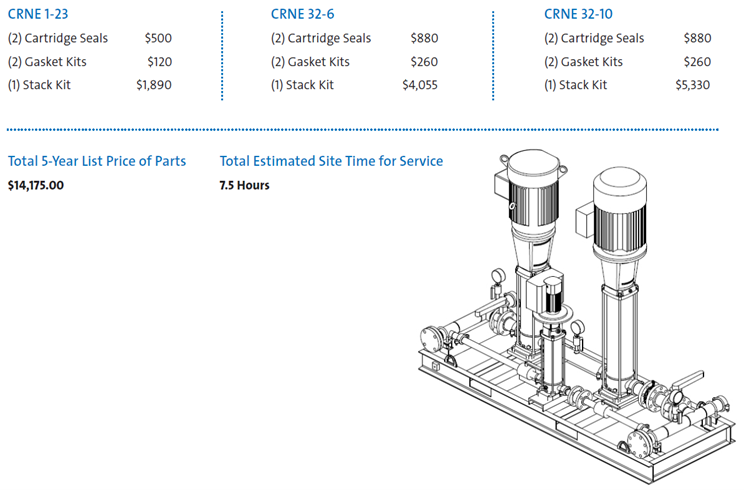

EXAMPLE

The following itemizes the expected costs for 5-year maintenance cycle for a simplex Hydro HP system to demonstrate the savings potential. The data below addresses only the wear part costs and does not include the expected energy cost savings that come with integrated Grundfos controls.

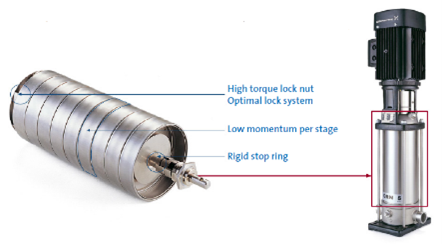

The Grundfos cartridge seal was introduced in a prior section. The other wear part kit is the pump rotating assembly, or stack kit, shown below.

Rotating Assembly (Stack Kit)

Rotating Assembly (Stack Kit)

• Tough

• Strong

• Heavy Duty

• Easy Replacement

In this example we will use a simplex Hydro HP with a CRNE 1-23 HS jockey pump and one high-pressure CR 32 Tandem using a CRE 32-6 feed pump and a CR 32-10 boost pump (see system drawing below). Over a 5-year use cycle, we will very conservatively suggest replacing the cartridge seals on each pump twice, and the stack kit in each pump once. With good water quality and proper installation, these intervals could be significantly longer. For estimating site labor cost, we will use 30 minutes for the cartridge seal replacement and 90 minutes for a stack kit replacement. The costs below are all published list prices.

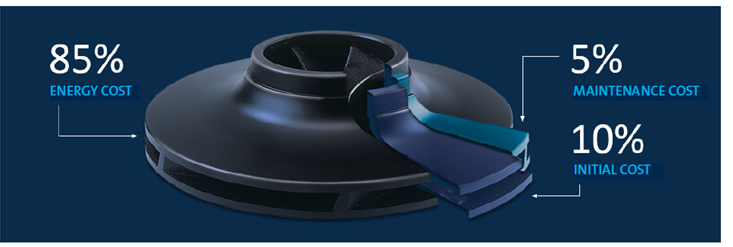

Energy Savings

We itemized above a conservative 5-year OPEX for servicing the Hydro HP. We also expect that the energy efficiency of the Hydro HP will yield additional cost savings.

Over the expected life span of a pump or a system, 85% of the total life cycle costs will be from energy costs. With the use of VFDs for motor speed control and the CU 352 for management of pump sequencing for best efficiency, we expect the Hydro HP to provide additional savings with energy use over its operational life.

EVALUATING THE TRUE COST OF OWNERSHIP

ADVANTAGES OF A PACKAGED APPROACH

In addition to all the advantages described above, the Hydro HP also comes with the added benefits of purchasing a fully engineered Grundfos pumping system:

• Single-source responsibility with a Grundfos 2-Year Warranty

• Smart integrated controls and pumps factory-matched for best performance and efficiency

• Pumps, controls and system fabrication, all by Grundfos in an ISO-9001 facility

• Factory testing

• Customizable systems to meet special conditions or facilitate future expansion

• After-market support from our national network of distributors and factory-authorized service centers

Grundfos Experience and Warranty

As compared to traditional high-pressure pump systems, Grundfos’ simple and reliable integrated design guarantees minimal in-house maintenance in minutes, which is critical to keep processes running smoothly. Known for their efficiency and adaptability, Grundfos CR and CRE pumps are the world’s leading vertical multistage centrifugal pumps with proven durability. The ROI from an energy-efficient Grundfos engineered system is comparatively realized within the first few maintenance cycles.

High-pressure pumping is a requirement for wash and clean in food processing, but the maintenance headaches and high energy consumption of old pumping systems does not have to be. Designed with the pain points of industrial plants in mind, the Hydro HP offers a smarter, more reliable system for today’s industries.

Learn more about Grundfos’ Hydro HP fully-integrated high-pressure booster systems at grundfos.us/hydrohp.