Taco Comfort Solutions offers self-sensing pumps that use variable speed pumping technology for maximum efficiency, reducing both utility costs and carbon emissions

Water Circulation Pumps & Circulators

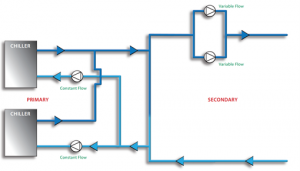

Taco’s patent pending Self-Sensing ProBalance technology utilizes a variable frequency drive (VFD) meant for constant flow chiller/boiler pumps and secondary variable flow pumps. The VFD self-sensing capabilities make fast, accurate, do-it-yourself system balancing easy and helps reduce contractor costs, expensive wiring and additional sensors.

Variable Speed Pumping Capabilities

Variable Speed Pumping Capabilities

• Integrated pump and drive

• Automatically responds to system demand changes

• No remote sensors

• No complex wiring

• Multiple modes:

– Constant flow

– Constant pressure

– Flow compensation

– Duplex pump alternation

• Balancing through reduced speed, not false head

• Reduced speed increases equipment life

• Auto-adjusts over the life and fouling of the system

• Lowers install costs – no sensors or wiring

• No error in setpoint

• Improved system efficiency and performance

Parallel Pumping Configuration

The Self-Sensing Modulating Pump Controller (MPC) stages individual pumps in parallel configuration for best overall pumping efficiency. The MPC can operate two to four pumps in parallel for maximum efficiency. The Sensorless Parallel Pump Controller provides single building automation systems connection in either BACnet MSTP or Modbus RTU and is enclosed in a NEMA 4X certified enclosure.

Pump Protection and Electrical Safety

The Self-Sensing Series also features automatic alerts with optional shutdown for no-flow, dry-run and end-of-curve operation. That means the seal is safe should someone forget to open a valve or to run the pump without water. What’s more, the unit is electronically protected for overload and locked rotor conditions per UL 778 and CSA C22.2 No. 108, so the motor is protected — a real crowd pleaser for insurance companies.

Presenting DIY Balancing

Every HVAC pump needs to be balanced by an expert who must account for construction variables and safety factors. Whether constant or variable speed, the balancing process has to be addressed at commissioning and startup. But what if you could zero in on the true system resistance without inducing false head and balance the pump yourself? You can with Taco’s Self-Sensing ProBalance technology.

The Benefits of Do-It-Yourself Balancing

• Control over construction schedule and subcontractors

• Reduced installation costs

• Capable of helping an LEED team get a job into their budget

Savings Analysis

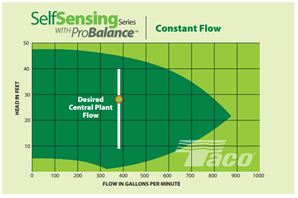

Balancing a constant flow system with Taco drives saves lots of energy and increases pump life dramatically. For example, a pump that would have run at 1750 rpm @ 60hz is balanced with technology to run at 1458 rpm @50hz. Now the pump consumes 57% of the horsepower and runs 291 fewer revolutions per minute. The savings translate to 419,000 cycles per day or 150M fewer cycles every year. As a result, the pump lasts longer, requires less maintenance and uses less energy. Using self-sensing technology, a Tennessee hospital saved $3,000 in yearly electrical costs on 100 HP chiller pumps running at 47 hz instead of 60 hz.

High Performance Packages

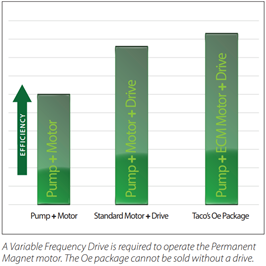

Take your system to the next level with Taco’s Optimized Efficiency Packages. In today’s environment, hydronic systems need to be up to date with the latest technology. The market is now driven towards high efficiency solutions by ever-increasing regulations and environmental factors.

Take your system to the next level with Taco’s Optimized Efficiency Packages. In today’s environment, hydronic systems need to be up to date with the latest technology. The market is now driven towards high efficiency solutions by ever-increasing regulations and environmental factors.

By utilizing Permanent Magnet motor technology, Taco is bringing the largest ECMs available to the hydronic industry. In combination with Taco pumps, R.F. MacDonald Co. aims to optimize your overall efficiency with the latest technology available. Don’t get caught wishing you had a more efficient system. Lead the charge with pumps that exceed regulations. Utilize the latest technology available and decrease total cost of ownership.

Reasons to Optimize

• Longer service life, more uptime and higher reliability

• Increased performance, quieter & smoother operation

• Reduced lubrication frequency, resulting in lower maintenance costs

• Low operating temperature

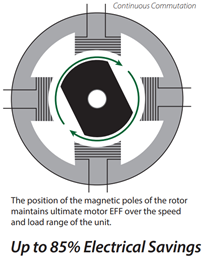

• Flatter motor efficiency profile than the equivalent induction motor as the speed & load decline

The Oe Package

The Oe Package

The Taco Oe package is designed to increase total efficiency and exceed the regulations passed down from the DOE. In doing so, you get a complete package that saves on energy and the environment. The Oe package is simple. Each Taco pump receives a Permanent Magnet motor and VFD to increase savings at slower pumping speeds. Taco is the first company to bring ECM technology to hydraulic pumps up to 30 HP.

Increase your performance with the Taco Self-Sensing drives included with the Permanent Magnet motor pumps for the best energy rating Taco has to offer. The added benefits of DIY balancing will decrease the total cost of ownership over the lifetime of the pump.

Self-Sensing with ProBalance Pump Options

1. Taco SKS and SKV Self-Sensing Vertical Split-Coupled In-Line Pumps

1. Taco SKS and SKV Self-Sensing Vertical Split-Coupled In-Line Pumps

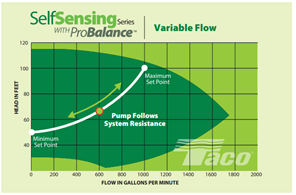

The variable frequency drive’s self-sensing capabilities make fast, accurate, do-it-yourself system balancing easy. The constant flow mode is self-balancing and automatically adjusts pump speed to maintain a user-defined flow setpoint. In variable flow mode, the pump adapts to system pressure variations and automatically follows the system resistance curve to meet demand. These capabilities allow you to use these pumps for all your pumping needs, both constant flow chiller/boiler pumps and secondary variable flow pumps. In all applications, they help reduce contractor costs, expensive wiring and the need for problematic external sensors.

2. Taco SCI and SFI End Suction Pumps

2. Taco SCI and SFI End Suction Pumps

The first self-sensing end suction pumps with integrated VFDs permit fast, accurate balancing. They help to reduce balancing contractor costs, eliminate expensive wiring and the need for external sensors. The New SCI close-coupled end suction pumps and SFI frame-mounted end suction pumps provide superior reliability and ease in installation for heating, air conditioning, pressure boosting, cooling water transfer and water supply applications. All meet the latest standards for hydraulic performance and dimensional characteristics for quiet, dependable performance.

• Self-Sensing bypass option – an advantage for engineers who seek to bypass the variable speed control.

• Customers can order either a NEMA 1 drive with an ODP motor or a NEMA 12 drive with a TEFC motor.

• Easy-to-replace, slip-on shaft sleeve to facilitate easy field maintenance.

• Dry shaft design to protect pump shaft by eliminating contact between the shaft and the circulating fluid.

• Flush seal line taps allow installation of filter to protect seal from non-condensable particles in the system.

• Pressure tappings on suction and discharge connections are standard.

• SFI frame-mounted end suction pumps feature an improved bearing frame design with sealed-for-life bearings that meet all industry requirements for a minimum bearing life of 60,000 hours. The improved design also incorporates a unique sealing system which prevents the migration of water into the bearing frame.

3. Taco 00e Series VR ECM High-Efficiency Circulators

3. Taco 00e Series VR ECM High-Efficiency Circulators

A convergence of efficiency, simplicity and technology within this new generation of wet rotor circulators. The 00e Series (VR15 – VR30) are versatile web-enabled, wet rotor, variable speed commercial pumps for chilled and hot water applications. Internet access and settings make installation, setup and service easy. The ECM motor saves up to 85% of the electrical energy compared to conventional pumps. Multiple operating modes make this pump a perfect choice for most applications.

• Simple user interface on pump-face to enable settings, eliminating need for laptop

• Real-time performance readouts for flow, power consumption, speed and head values

• Self-Sensing Dynamic Auto, Proportional & Constant Pressure plus Manual Variable Speed modes provide extensive application flexibility

• On board 0-10Vdc two-way control adjusts speed/head to meet system demands from external control

• ModBus control and performance feedback for advanced Building Management/Building Automation Systems

• RJ 45 input / output for ease of networking

• Relay outputs for remote monitoring of pump status and digital inputs for external enable / disabling

• Simple Main / Standby and Parallel Pump operation (parallel pumps run together as needed) via standard ethernet cabling

Contact R.F. MacDonald Co. for your Taco Comfort Solutions Self-Sensing ProBalance technology needs