R.F. MacDonald Co. is the new representative for Process Combustion Corporation in CA and NV, offering state of the art pollution control systems for all your plant needs

Process Combustion Corporation (PCC) is one of the most respected pollution control equipment designers in the industrial market. Since 1969, PCC has designed and provided systems for the chemical, petrochemical, refining, automobile, pharmaceutical, textile, rubber, converting, metals, food, sulfur, carbon, engineered wood-products and the pulp/paper industries. R.F. MacDonald Co. is proud to announce we will be bringing their solutions to our customers in California and Nevada.

PCC is an American-owned company headquartered in Pittsburgh, Pennsylvania with production, sales and distribution operations around the world. From its manufacturing facility in Pittsburgh, PCC designs and supplies combustion, heat transfer & pollution control systems for industrial applications. Their creative designs minimize system costs, especially energy consumption, while meeting environmental regulations.

“Our expertise and experience in the thermal and biological oxidation of gaseous and liquid wastes, NOx abatement, VOC destruction, odor control and acid gas systems is complemented by our knowledge, understanding and practical know-how specific to heat recovery boilers, heat exchangers, wet scrubbers, baghouses and electrostatic precipitators,” President and Chief Executive Officer Will Huebner said.

Oxidation Technologies

Broad Experience – PCC designs, manufactures and supplies thermal and biological oxidation technologies for a wide range of pollution control applications. PCC’s system designs promote the chemical reaction (thermal/biological oxidation) between the pollutant compound and oxygen (O2) in air. Engineering expertise ranges from highly technical to pre-engineered.

NOx Reduction – PCC’s technically advanced Low NOx burners and multi-stage Low NOx combustion systems minimize or eliminate NOx emissions, meeting California’s emissions requirements technically and economically.

PCC supplies a range of solutions to meet all air pollution control needs. All systems are guaranteed to meet the end user’s specification and performance requirements.

• Direct fired Thermal Oxidizers

• Multi-stage Thermal Oxidizers

• Recuperative Thermal Oxidizers

• Regenerative Thermal Oxidizers

• Flameless Thermal Oxidizers

• Biological Oxidation

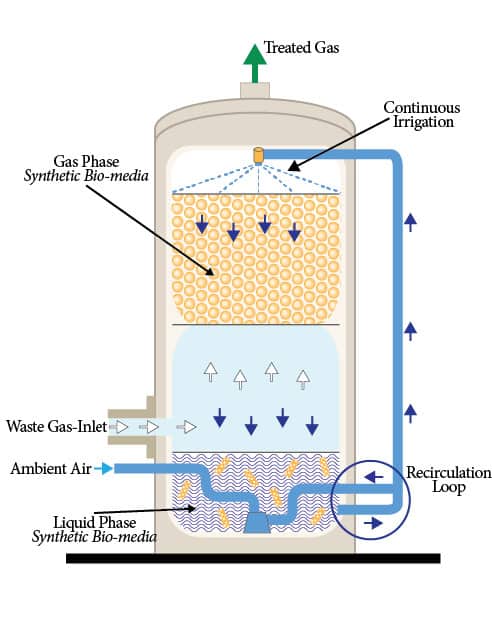

PCC’s Dual-BioPhase Bio-Oxidation Technology provides an economical and environmentally friendly method of treatment for a wide range of organic and inorganic air emissions. Pollutant compounds that dissolve in water are treated in the water phase while compounds that remain in air are treated in the gas phase. Bio-oxidation generates 20x less CO2 than thermal oxidation.

PCC’s Dual-BioPhase systems are fully automated and custom-engineered to meet the performance requirements for most odor or volatile organic compound (VOC) applications.

The replacement of Regenerative Thermal Oxidizers (RTO) with PCC’s Dual-BioPhase Bio-Oxidation Technology is becoming more common. There are numerous applications that lend themselves to the replacement of the RTO with Dual-BioPhase technology. A minimum of a 60 percent operating cost reduction can be realized as well as an 80–90 percent reduction in greenhouse gases, along with the elimination of NOx.

R.F. MacDonald Co. is available to immediately handle all PCC sales and service in California and Nevada.