R.F. MacDonald Co. completes a low NOx burner retrofit on a glycol heater used to sterilize winemaking equipment at a Northern CA winery

Hot Water should be 180 degrees for use in sanitation.

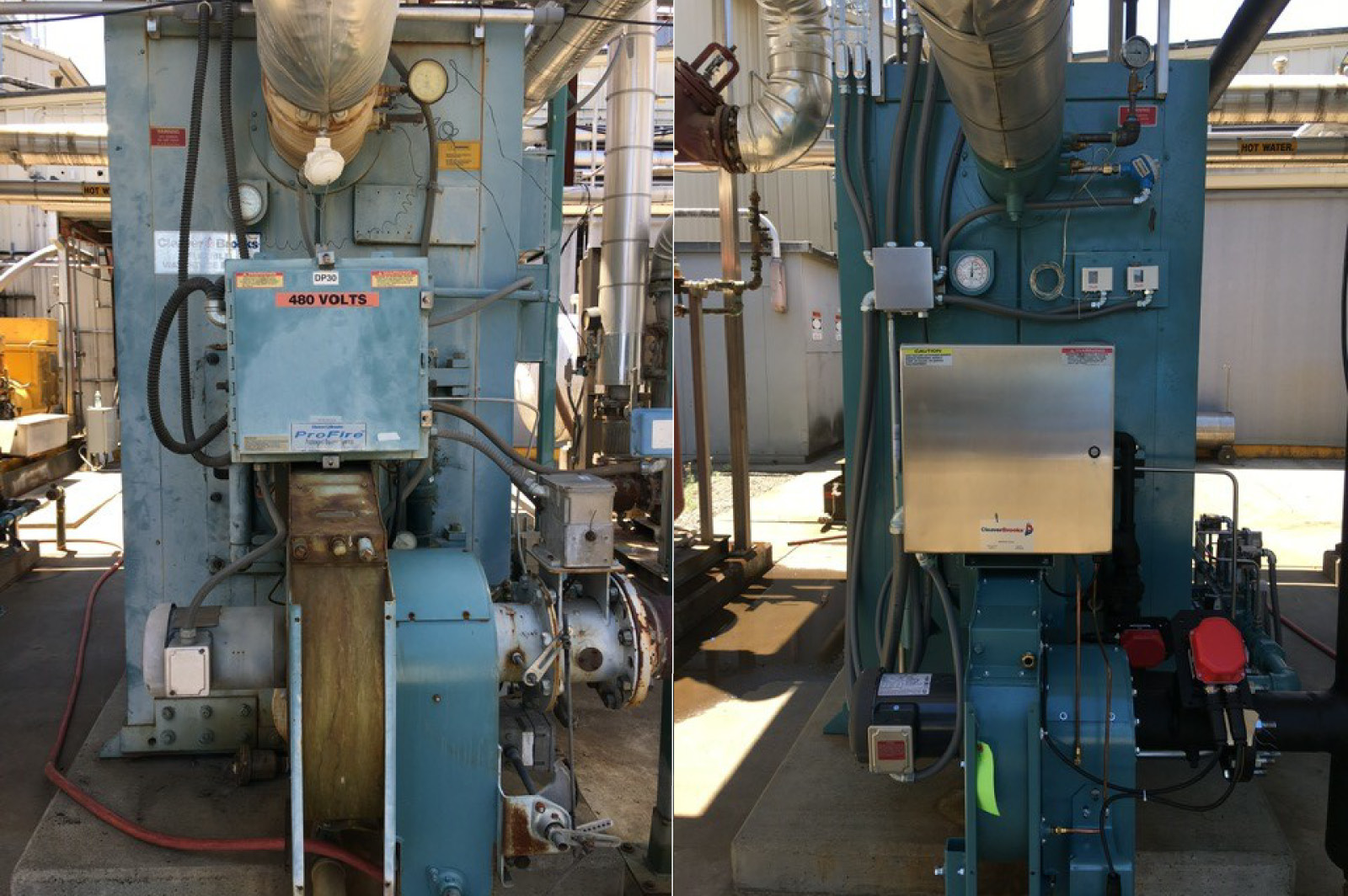

Due to boiler regulations in the Bay Area, R.F. MacDonald Co. was called to upgrade a Cleaver-Brooks Flextube process hot water boiler, which had an older model ProFire Cleaver-Brooks burner. The older burner was upgraded with a top-of-the-line Cleaver-Brooks NTH-25 Ultra Low NOx burner (2.5 MBTU) with a Hawk ICS control panel.

The RFMCO Service Dept, known for its quality of service, cleaned & painted the boiler after the job was done.