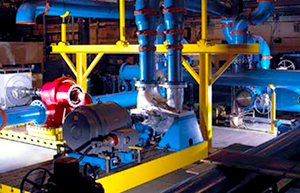

Many factors go into pump testing including safety, cost, lead times, customer production and efficiency across the testing and delivery cycle

Summary

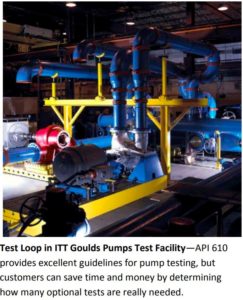

The latest edition of API Standard 610 has clarified industry guidelines for pump testing, but new customers still often over-specify testing for new pumps. By understanding the nature of pump test results, the available test methods, and how to evaluate which defects are consequential, pump customers can learn about balancing the many factors involved in testing decisions — including safety, costs, lead times, customer production, and efficiency across the testing and delivery cycle.

The latest edition of API Standard 610 has clarified industry guidelines for pump testing, but new customers still often over-specify testing for new pumps. By understanding the nature of pump test results, the available test methods, and how to evaluate which defects are consequential, pump customers can learn about balancing the many factors involved in testing decisions — including safety, costs, lead times, customer production, and efficiency across the testing and delivery cycle.

In assessing which tests are required, customers should consider the manufacturer’s reputation and integrity.

Manufacturers are required to perform pressure and performance testing on every pump they deliver. In some cases, no additional tests are necessary, and customers can rely on the manufacturer’s warranty to give them peace of mind.

API 610 details non-destructive tests for evaluating castings and welds. They fall into five relevant categories: visual, liquid penetrant, magnetic particle, ultrasonic and radiographic inspections. From first to last, they are increasingly effective at producing findings, and progressively more expensive. The reason for the expense is not so much the tests themselves, but the cost of repair procedures to address results — even though not all results require correction. In addition to the tests in these categories, API 610 presents many more optional performance tests for pumps.

Using a combination of API 610, the manufacturer’s standards and a heavy dose of common sense, customers can confidently specify only the tests and corrections they need to purchase pumps that will perform reliably and productively for many years.

API Standard 610

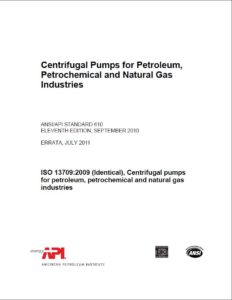

Very few business segments have as much need for rigorous safety and performance standards as the petroleum industry, and the pumps used to move hydrocarbon products are critical parts of the process. In 2010, the world consumed 1,383.2 billion barrels of oil and 3,169 billion cubic meters of gas.1 In an effort to spread best practices, the petroleum industry has issued standards by which pumps should be tested and operated. Published by the American Petroleum Institute, the ANSI/API Standard 610, Eleventh Edition, published in September 2010, is the latest version. The publication may be purchased directly from API at www.api.org/publications.

Very few business segments have as much need for rigorous safety and performance standards as the petroleum industry, and the pumps used to move hydrocarbon products are critical parts of the process. In 2010, the world consumed 1,383.2 billion barrels of oil and 3,169 billion cubic meters of gas.1 In an effort to spread best practices, the petroleum industry has issued standards by which pumps should be tested and operated. Published by the American Petroleum Institute, the ANSI/API Standard 610, Eleventh Edition, published in September 2010, is the latest version. The publication may be purchased directly from API at www.api.org/publications.

Bringing two world benchmarks together, API 610 now is identical with guidelines issued by the International Organization for Standardization, as ISO 13709:2009. The two standards are published as one, eliminating confusion for users worldwide.

Pumps play an essential role in extracting, refining and transporting petroleum products. It’s critical that those pumps perform to a high standard. Whether the goal is fire prevention, process integrity, or simply basic quality assurance, pump testing is a necessary step that, when executed properly, engages a number of stakeholders — ranging from specifying engineers and manufacturers, to customers and inspectors. The key for all of them is to agree on a set of tests that makes sense for each pump and application, without the over-testing that can run up costs and delay the completion of critical projects.

To be clear, API 610 is not intended for use by novices. It’s a detailed, technical document that requires a high level of engineering knowledge and experience to fully understand. Generally, however, most purchasing agents and specifying engineers should understand the nature and intent of the material in API 610. Everyone in the process will gain a greater appreciation of why certain tests need to be performed, and the criteria used to make those decisions. Before describing the testing, it’s important to understand the two potential stress points being tested — castings of pump components and the welds that connect castings and pipes.

Casting—Bronze Age Technology Meeting 21st Century Standards

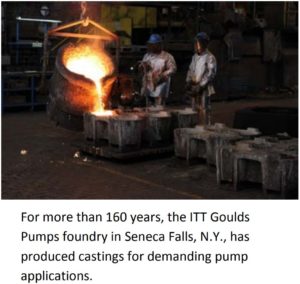

No discussion of pump reliability and testing can happen without understanding the casting process. It’s a widely used, centuries-old technology that involves pouring molten metal into a form, then letting it harden and removing the form to reveal the manufactured part.

No discussion of pump reliability and testing can happen without understanding the casting process. It’s a widely used, centuries-old technology that involves pouring molten metal into a form, then letting it harden and removing the form to reveal the manufactured part.

The truth about casting, in the Bronze Age like now, is that the process contains a range of challenges — from foreign-object contamination to shrinking. Non-destructive testing is one way to ensure that pump castings have integrity and will perform as intended. In addition, the conditions under which people make castings in foundries are unfriendly at best. Room temperatures are very high, the protective clothing can be uncomfortable, workers routinely handle highly dangerous materials and the job itself is very physically demanding.

Since castings are still an integral part of manufacturing pumps, the process and its potentially negative side effects continue. Fortunately, pump manufacturers, with improved tools and the benefit of decades of experience, have become very adept at designing and making high-quality castings.

Welds—Tested to Ensure a Happy Marriage of Metals

Along with the casting process, welding is the other key area that is the subject of nondestructive testing. Welds join pipes to castings, or pipes to other pipes — also with inherent risks. The quality of welds is dependent on the procedure used and the individual performing the work.

Along with the casting process, welding is the other key area that is the subject of nondestructive testing. Welds join pipes to castings, or pipes to other pipes — also with inherent risks. The quality of welds is dependent on the procedure used and the individual performing the work.

Because there are different metal combinations involved with building pumps, welders need to be qualified to work with the exact materials involved with the project. A good question to ask is how many times a given welder has performed specific procedures. Customers have the right to ask what weld procedures will be used, and to see the qualifications of the welders.

Common sense also suggests that not all welds need to be tested. A customer might choose to test 10 percent of the pipe welds in a set of pumps. If they all pass, the customer could logically assume that the quality on all the welds is good. Because there are so many welds on a typical pump skid package, if one defect is found among the 10 percent, that could be sufficient cause to continue inspecting.

Welds also are used to repair pump castings. Throwing out the casting and starting over is seldom economically viable, so welding becomes a valuable technique for restoring the pump to required standards.

Five Major Non-Destructive Test Categories for Castings and Welds

New in the API 610 Eleventh Edition is Table 14 — Pressure casing material inspection requirements. This new table clearly maps out when certain tests should be done. The table takes into account five different test methods: visual inspection, magnetic particle inspection, liquid penetrant inspection, ultrasonic inspection and radiographic inspection.

Visual Inspection. Inspectors look for defects in pump castings and welds. Visual inspections are conducted at no extra cost to the customer.

Visual Inspection. Inspectors look for defects in pump castings and welds. Visual inspections are conducted at no extra cost to the customer.

Liquid Penetrant Inspection. Using a combination of dye and ultraviolet light, inspectors look for surface cracks that generally are not visible to the naked eye.

Magnetic Particle Inspection. Used on magnetic castings such as carbon steel, this technique involves distributing a colored magnetic powder on the casting, then running an electric charge through it and noting where the powder forms around defective areas. This method is designed to show defects and cracks that visual- and liquid-penetrant inspections may not reveal. For non-ferrous metals such as stainless steel, this method cannot be used.

Ultrasonic Inspection. A fourth testing category is ultrasonic; this method is used to test casting wall thickness and subsurface defects in higher-stress applications. Also, ultrasonic wave reflections are used to identify subsurface defects in bar stock such as shafts.

Radiographic Inspection. The most thorough — and most expensive — method is taking an X-ray of the pump. Radiographic inspections will reveal subsurface defects that no other method can detect. This process requires correct positioning of a film underneath the pump that isn’t always possible or practical.

The Variable Price of Failure

The basis behind much of pump testing is: What is the impact if this pump fails?

To sharpen the point, there is a world of difference between pumping water from a well, and pumping hydrocarbon at temperatures higher than its auto-ignition level in a refinery. A leak in the first example will have virtually no impact, but a leak in the second could cause a catastrophe.

This is the lens through which pump tests should be selected. It’s the role of the customer to assess their own price of pump failure, and to work with their pump manufacturer to determine the testing schedule that brings them the right knowledge, at the right balance of financial investment and time.

Determine the Value of Performance Tests

If testing is a way of predicting long-term pump reliability and performance, is more testing better? In the many factors to consider when testing pumps, it’s generally acknowledged that customers should take a conservative approach, but should not build in extra obstacles to final approval. Part of that process is simply asking what the benefit is for each specified test, with a determination of how critical each is to a final decision.

The key is to determine which tests truly add value. After all, API 610 describes nearly 50 tests that could apply, and all have an impact on the potential time and money spent to reach the final testing goal. Customers or their representatives should read the API standard to truly understand what those tests entail, then discuss testing options with their pump suppliers to determine the impact that planned testing will have on costs and project lead times.

Witness testing, when customers or their representatives travel to see one or more tests in person, essentially means that the test will be conducted twice. Manufacturers typically conduct the test before the customer sees it so customers need to make certain that witness tests are worth the required expense and time, which can be one to two weeks per witness test.

Testing sequences are critically important, so customers should map all of the test requirements up front. That way, both customers and manufacturers understand what the critical test points are. Accordingly, some tests are “hold points,” and manufacturers will not proceed past them without consultation.

Mandatory Pump Tests

Regardless of any other tests that are done on a pump for API 610, manufacturers always perform two simple but critical exams: a hydrostatic pressure test and a performance test.

For the hydro test, all the casing openings are blocked and the casing is pressurized with water. API standards specify that all pumps must be pressurized to 1.5 times the design pressure that the pump will experience in the field.

The performance test simply involves operating the pump at specified hydraulic conditions, and proving that it performs at its guaranteed levels.

API 610 offers detailed instructions for dozens of other pump tests too. The document lists a default set of tests that are recommended for every pump along with optional tests, distinctly marked with a bullet, from which pump customers can choose. The key for customers is understanding when it’s necessary to order the optional tests.

Consulting the Manufacturer

API pump-testing standards now offer criteria that can help customers decide which tests to order. In addition to the API standards, however, there are other factors that customers can consider to ensure pump safety and reliability.

One is the manufacturer’s internal quality requirements. Customers should ask for a list of these requirements and use them as part of their own testing checklist. Knowing the manufacturer’s requirements can help save customers from over-specifying and overspending on tests. Ask for proof of experience from the manufacturer to gain confidence in their technical skill.

Another level of comfort for customers is the manufacturer’s warranty. The warranty will be in place even if a defect is identified in testing, providing customers with a high level of confidence.

Facilities can tell their own story. In evaluating a manufacturer’s welding operation, common sense is a guide. If the welding area looks clean and organized, that’s likely a good sign. Ask to see evidence of process improvement strategies and initiatives as implemented throughout the operations. You should see the checklists and process charts that form the foundation of systematic process improvement plans. Customers also can request weld procedures and qualification records on individual welders.

Finally, when considering which pump tests to order, perhaps a first consideration is how experienced the manufacturer is at making that particular model.

Should All Tests Be Performed and All Findings Addressed?

No one wants a pump with a “defect,” but the question becomes: is the finding detrimental to pump performance?

It’s understood in the industry that pump customers pay more for higher levels of testing. Customers must work with pump vendors to determine whether additional, optional testing is an appropriate investment based on the applicability of potential findings. When tests return results of varying degrees, customers must decide how to address them. The factors in those decisions include the criticality of the pump or component, required lead times, and the possible adverse impact of duplicative or inefficient tests. In some rare cases, manufacturers may have to scrap a bad casting. Most defects, however, can be physically ground out and repaired with a weld — much the same way that a dentist would remove tooth decay and fill a cavity.

Even though the likelihood of finding a defect increases with each inspection level, none of them tells the customer whether any given defect will result in a pump failure. In many cases, for example, a small surface crack won’t matter, because there is no stress on that crack.

API 610 provides information on how to test pumps, guidance on interpreting the results, and definitions of minor and major findings. Still, there inevitably will be discussions between customers and manufacturers about the levels of specific defects, and especially whether they are in critical areas of the pump that must withstand high pressure.

For example, consider the use of radiographic testing on a pump that would be used in a noncritical application. According to Table 14, visual inspection is all that’s required. Any additional defects that might be found using radiography never would be detected using only visual inspection, and what’s more, the defects detected by radiography wouldn’t impact the performance of the pump in the field.

Aligning Customer Expectations with API Standards

Independent engineering contractors also may add tests from API 610, and customers should verify that all such additional tests will add value. It’s prudent for all parties to agree in advance on the most useful tests for each pump ordered.

Independent engineering contractors also may add tests from API 610, and customers should verify that all such additional tests will add value. It’s prudent for all parties to agree in advance on the most useful tests for each pump ordered.

Manufacturers can help. ITT Goulds Pumps recently consulted with an Asian oil company to update their pump-testing specifications, which aligned the company with API Standards and a philosophy of specifying needed testing, but not over-testing.

For obvious reasons, over-testing is not an issue for manufacturers. After all, the more tests customers order, the more manufacturers get paid. Even so, managing tests wisely is prudent for all parties, because it’s a service to customers that can save them time and money. The practical customer, however, guards against over-testing by taking a balanced approach that considers the criticality of the pump, test costs, lead times and more.

One thing is certain: if the pump customer’s goal is to create a philosophy of testing that fits pump usage and risks, that plan must always begin with the industry’s guidebook for pump testing — the API 610 Standard.

Source: Goulds

Original Title: Meeting and Exceeding API Standards: How Much Testing Do Pumps Really Need?

Written By: John Bailey, API Global Product Manager

Marc DeSilva, Global Product Director, Oil & Gas

Plant Performance Services Group, ITT

About ITT and ITT Goulds Pumps

ITT is a diversified leading manufacturer of highly engineered critical components and customized technology solutions for growing industrial end-markets in energy infrastructure, electronics, aerospace and transportation. Building on its heritage of innovation, ITT partners with its customers to deliver enduring solutions to the key industries that underpin our modern way of life. Founded in 1920, ITT is headquartered in White Plains, N.Y., with employees in more than 30 countries and sales in a total of approximately 125 countries. The company generated 2011 revenues of $2.1 billion. For more information, visit www.itt.com.

ITT Goulds Pumps is the world’s leading manufacturer of pumps for a wide range of industrial markets—including oil and gas, chemical, mining, power generation, pulp and paper, and general industry. As the only manufacturer to make digital monitoring standard on every process pump, ITT Goulds Pumps continues to lead the industry in both mechanical pump design and the adoption of smart technologies. For more information, visit www.gouldspumps.com.

©Copyright 2012, ITT Goulds Pumps