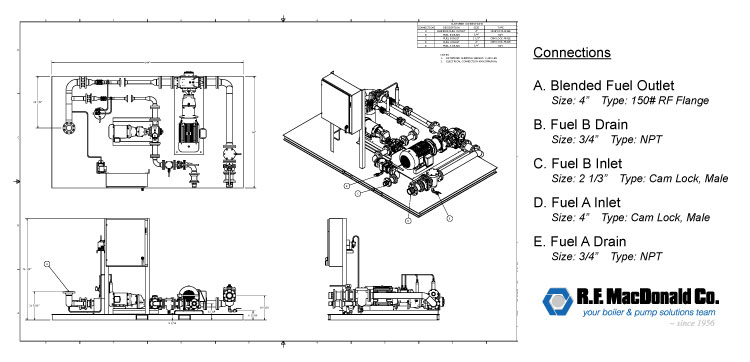

R.F. MacDonald Co. showcases this recently fabricated pump skid used to load/unload BioDiesel contents.

This custom system consists of two (2) self-priming pumps with associated controls in accordance to specific flow, head, and material capabilities.

The skid base is constructed for safe transportation while utilizing a forklift and suitable for outdoor operations. The system incorporates an Allen Bradly Compact Logix control system with an Automation Direct 7″ touchscreen operator interface, logic processor, and I/O modules to be included. This mounted technology will be used to control the blending percentages of the pumping material (e.g. BioDiesel) and total output volume based on the operator input. The system will be capable of providing blending of 5% to 25% by volume of Bio-Diesel into the Renewable Diesel line. The system will also provide a printout when completed.

Instrumentation includes:

- NEMA4X motor starter panels

- NEMA4X main control panel

- Independent Bio-Diesel Flow meter and pneumatic flow control valve

- Independent Renewable Diesel Flow meter and pneumatic flow control valve

- Thermal Printer for reporting

- Control and instrumentation for air purging and fuel purging back to tank