Camus DynaFlame hot water boilers and Taco Comfort Solutions pumps installed as part of an innovative flash détente system at a Central Valley winery

Flash détente is a relatively new technology invented in France in 1990, according to Wine Business Monthly, with the technology first being used in the U.S. in 2009. The flash détente system uses a thermovinification process during maceration to improve wine quality and modifies the body and flavor of the wine to match consumer requests.

About Flash Détente Technology

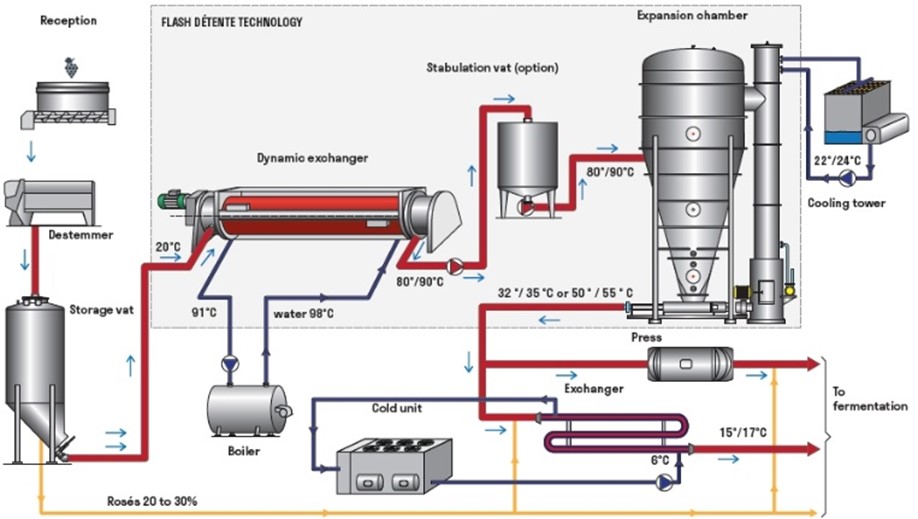

According to Pera Pellenc, a wine equipment manufacturer in France, the flash détente thermovinification process uses a boiler to supply hot water to a heat exchanger for fast heat treatment. The grapes are brought up to a high temperature and then immediately cooled down through pressure reduction.

“The crushed grapes are flash heated to 185°F and then transferred to a vacuum chamber where the berries are cooled quickly,” Pera Pellenc said.

The juice can be fermented as is or added back to the skins for further skin maceration to extract more tannins and the flavor condensate can also be added back if desired.

The process is controlled by a programmable PLC, which regulates two operating parameters: temperature and maceration time. When the grapes leave the heating chamber, the temperature will either be set at 158°F for hot pre-fermentation maceration or 185°F for flash détente thermovinification.

Traditional vinification

Grapes fermented after flash

Cost Effective Flash Heating

• Reduces pumping over

• Fermentation volumes up using the same amount of energy

• Better temperature control during fermentation

• Better coolant exchange during fermentation

• Shortened fermentation duration

• Uses entire volume of tank

• Stronger and faster alcoholic fermentation

• Easier tank drainage (if vinification in liquid phase)

• Reduced heating costs thanks to greater flexibility in harvesting dates

• Continuous process up to the alcoholic fermentation

• Non-stop operation possible

• Improved cellar capacities to produce new styles of wine or juice

• Optimized cellar with more opportunities for the vinification team

Source: Wine Business Monthly, Publication for Wineries and Growers

Flash Détente Reaching Critical Mass (2018)

Source: Pera Pellenc, Manufacturer of Winemaking and Vinification Equipment

Winemaking Equipment: Flash Détente thermovinification