Cleaver-Brooks SBR-5 Burner achieves the lowest emissions while maintaining the highest efficiency at 5 PPM NOx emissions with 3 percent O2 across the firing range

The new Cleaver-Brooks SBR-5 burners are designed for a variety of boiler types such as firetube and watertube boilers. Capable of less than 5 ppm NOx emissions with FGR, the ProFire SBR-5 series features a unique firing head design to achieve controlled combustion leading to ultra-low emissions with 3 percent O2. Consider the SBR-5 burner to meet California’s strict emissions regulations.

Product Overview

• Available to <5 ppm NOx with FGR

• ~3% O2 across a wide load range

• Up to 6:1 turndown ratio when firing natural gas

• Dual fuel capability

• Fuel switch over without mechanical adjustments

• Ultra-Low-NOx Emissions as low as 5 ppm achieved with FGR

• Natural gas fuel option from 10.5 to 42 MMBTU/hr

• Capable of firing ASTM 2D-S15 (ultra-low sulfur diesel) as a backup fuel at NOX levels below 40 ppm

• Maximum Efficiency provided by standardized parallel positioning

• Uniform Flame for equal heat transfer allowed by premix fuel

• Easy Access air housing for internal components

• Silent operation with an advanced combustion air fan wheel; Less horsepower and less noise

• Induced FGR modulating valve

• Ultra-Low-NOx/CO achieved without a fragile surface combustion burner head

• Integrated Controls with remote IoT monitoring capabilities

• Process Steam

• Industrial Process

• Waste Heat Recovery

• Hospital and Healthcare

• Laundry and Dry Cleaning

• Refineries and Petrochemical

• Healthcare, Education & Commercial

• Food & Beverage

• Manufacturing, Pulp & Paper

• Oil Sands, Petroleum & Refineries

• Government, Military & Utilities

• Chemical, Pharmaceutical & Biotech

Maximum efficiency: Forced-draft design controls the air and fuel mixture, resulting in complete combustion

Low maintenance: Modern, reliable controls maintain adjustment for dependable performance

Save energy: Retrofit your boilers with high-efficiency, state-of-the-art burners

Attributes

Controls Help Make the Difference

The Hawk is a complete boiler room solution. It not only integrates the boiler/burner, heat recovery and feedwater systems but provides complete boiler room data to remote communication systems such as building automation systems, SCADA packages and other remote monitoring systems. All Hawk packages come with

• Parallel positioning

• Stack temperature with high cutoff set point

• Thermal shock protection

• Dual set points

• Touch screen HMI

• PLC-based combustion control

• Alarm and historical monitoring

Hawk controls also offer remote IoT Monitoring. Cleaver-Brooks’ Prometha Connected Boiler Solutions provide actionable insights into your boiler operation, and help you

• Access boiler insights from anywhere, 24/7/365

• Increase operational efficiency

• Lower total cost of ownership

• Prevent and reduce downtime

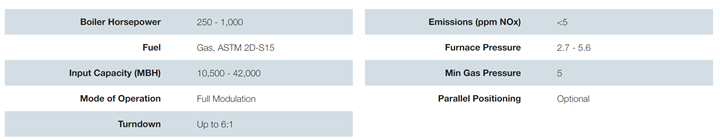

Profire SBR-5 Technical Data Sheet

*The recommended furnace conditions are based on CBEX firetube boilers. Operating conditions and performance criteria may be different if furnace diameter and length are smaller than the recommended values

*The recommended furnace conditions are based on CBEX firetube boilers. Operating conditions and performance criteria may be different if furnace diameter and length are smaller than the recommended values

Cleaver-Brooks provides a full line of high-quality, low-emissions burners that are specifically engineered to increase your boiler’s efficiency and decrease fuel costs and emissions. With the flexibility of multiple fuel options and the availability of high turndown burners, there is a Cleaver-Brooks burner appropriate for your commercial, industrial or institutional application. See all recommended burners.