There are many reasons engineers believe condensing boilers do not fit design applications, but most of these reasons are inaccurate due to outdated information

Condensing boilers have the latest technology to replace standard, non-condensing boilers for most applications. Within the condensing boiler segment, a variety of technologies are available. High mass firetube condensing boilers have been developed to overcome many obstacles and can be piped in a variety of systems with success.

MYTH #1 – YOU NEED TO MAINTAIN 180°F HOT WATER SUPPLY FOR THE SYSTEM TO WORK

Prior to condensing boilers, it was common for systems to be designed with high hot water supply temperatures in the range of 180°F to 200°F. One of the main purposes of the high hot water temperature was to satisfy the hot water return temperature back to the boilers since a higher hot water supply temperature results in a higher hot water return temperature delivered back to the boiler.

The difference with a condensing boiler is that hot water return temperature is the driving force behind condensing boiler efficiency. In condensing boilers, the goal is to generate as much condensation as possible because the heat exchanger is constructed of a corrosion resistant material such as stainless steel or aluminum specific to the application. In addition to the hot water return temperatures, coils can also be designed to satisfy the load based on varying hot water temperatures.

MYTH #2 – YOU NEED TO MAINTAIN A 20°F SYSTEM ΔT

Myth #2 is similar to myth #1 in that older systems typically maintain a low ∆T in order to keep the hot water return temperature above condensing conditions. In condensing systems, temperature differentials of 30°F or higher can be designed to increase boiler efficiency by lowering the hot water return temperature back to the boiler. Increasing the temperature differential between the supply and return water has the added benefit of reducing the flow rate since the flow rate is related to the overall heat output of the coil. Therefore, the higher the ∆T, the lower the flow rate, which results in smaller pumps, less horsepower required to move the fluid, smaller piping, and other system benefits.

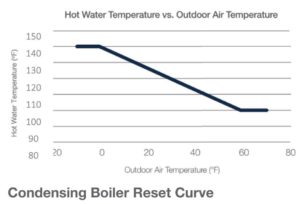

MYTH #3 – HOT WATER RESET DOESN’T WORK

Hot water reset involves resetting the hot water supply temperature based on outside air conditions. The theory behind resetting the hot water supply temperature is that as the outside air temperature increases from the design condition, the amount of heat required to satisfy the space load decreases. Similarly, as the space load decreases, it is also possible to heat the space with a hot water supply temperature less than the design condition, which uses less energy to heat the water to a lower set point.

Hot water reset involves resetting the hot water supply temperature based on outside air conditions. The theory behind resetting the hot water supply temperature is that as the outside air temperature increases from the design condition, the amount of heat required to satisfy the space load decreases. Similarly, as the space load decreases, it is also possible to heat the space with a hot water supply temperature less than the design condition, which uses less energy to heat the water to a lower set point.

With condensing boilers, the hot water reset functionality based on outside air is generally built in, making this a low- or no-cost item to implement within the system.

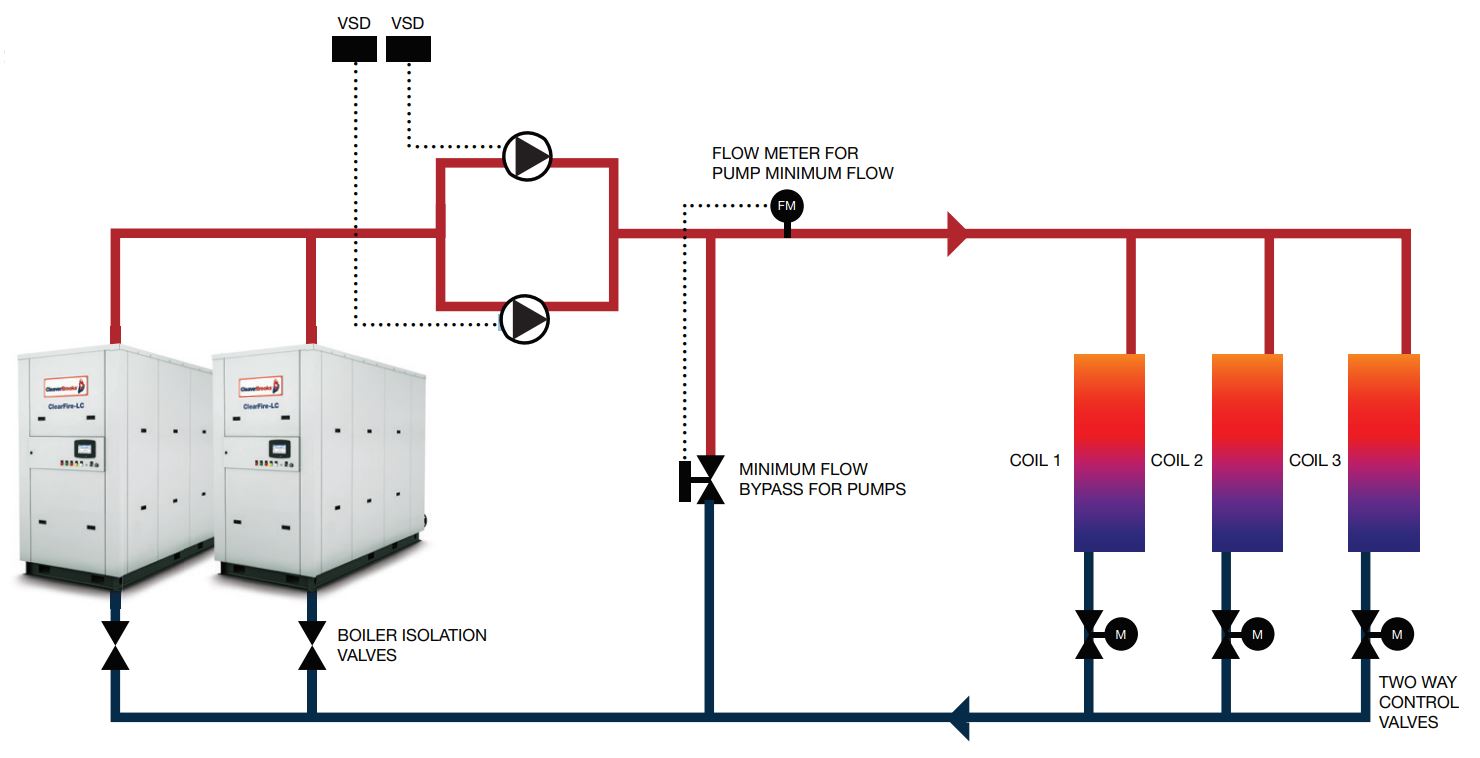

MYTH #4 – VARIABLE-FLOW-PRIMARY SYSTEMS ARE MORE COMPLEX

Hot water systems are generally known for using primary-secondary systems, which became the norm because non-condensing boilers cannot handle variable flow to maintain hot water return temperatures above condensing conditions.

Variable-flow-primary systems are simpler than primary-secondary systems because variable-flow-primary systems only require one set of pumps to handle everything in the system. Also, there is no mixing due to two hydraulically separate pumping loops and less equipment is required so there are fewer devices to control. In variable-flow-primary systems, there are three items that must be addressed for proper system operation all of which are standard and limit the need to learn new control algorithms or special sequences.

- A flow meter that can measure the water flow rate to the distribution system. In many designs, this is common practice for measurement and verification or for owners who are interested in tracking the energy consumption so it may already be part of the design.

- A minimum-flow bypass with a modulating two-way temperature control valve, which is the same control valve at all the heating coils in the system. These two items work in parallel with one another as the flow meter ensures minimum flow to the boilers and/or pumps is always maintained thus protecting the equipment. Many condensing boilers have very low- or no-minimum flow requirements.

- Another two-way temperature control valve is required for each boiler when there are multiple boilers operating in parallel. This control valve is a two-position isolation control valve that remains closed when the boiler is off and opens when the boiler is on. This is also typically a function that the boiler controls can perform. The purpose of the control valve is to prevent flow through the boiler when the boiler is off, which results in bypassing and mixing with reduced hot water supply temperatures.

Figure 1: Minimum-flow-bypass control logic in a variable-primary-flow system.

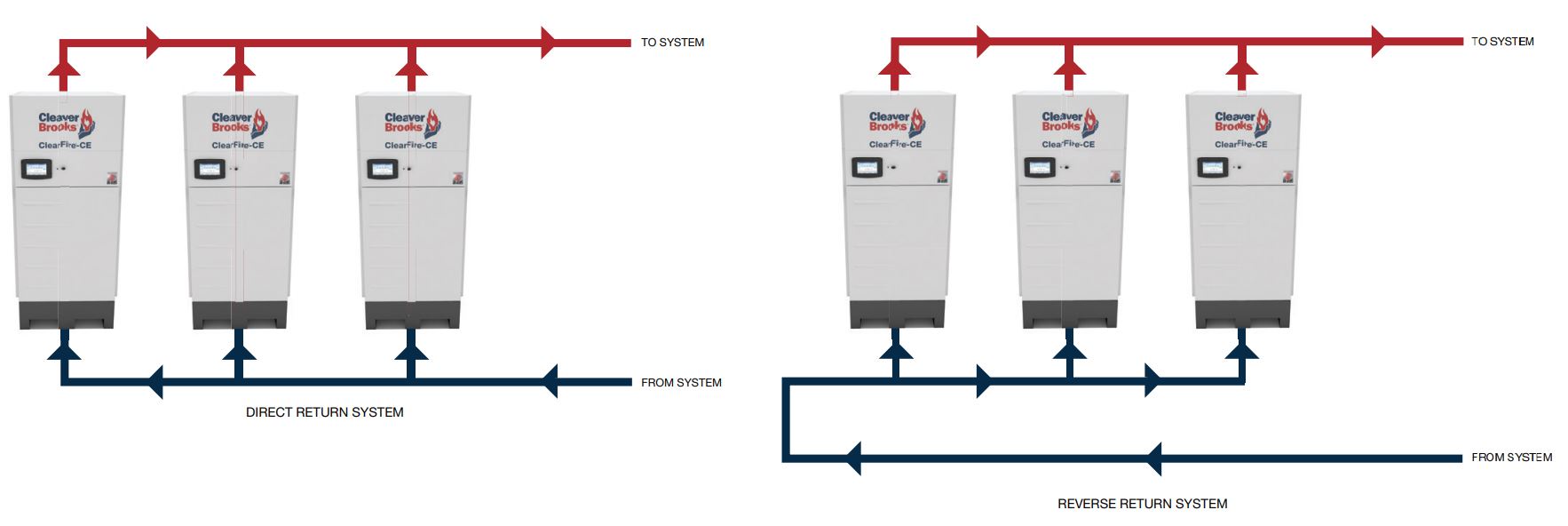

MYTH #5 – REVERSE RETURN HELPS BALANCING

Piping distribution systems that deliver water to the system heating coils are designed using one of two strategies, either direct return or reverse return.

Reverse return is a concept that evolved to solve the problem with direct-return systems. In a reverse-return configuration, the first coil to receive water from the central plant is designed to be the last coil to return water to the central plant. In theory, this equalizes the distance the water is pumped when distributed in the piping network and attempts to create a relatively equal pressure drop for each coil circuit.

Figure 2: Direct-return compared to a reverse-return piping configuration.

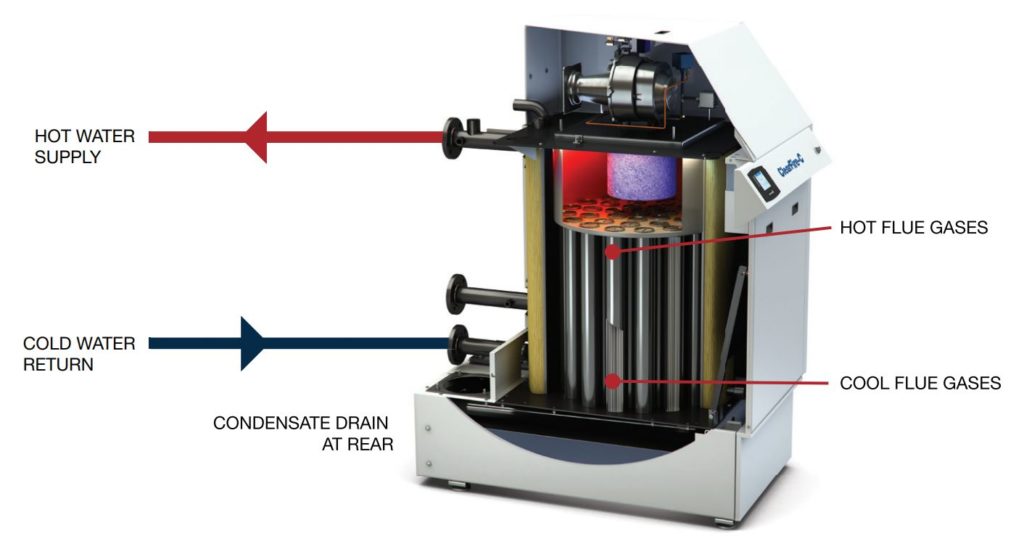

MYTH #6 – HOT WATER SUPPLY TEMPERATURE IS IMPORTANT FOR EFFICIENCY IN CONDENSING BOILERS

Hot water supply temperature is part of the equation in defining heating coil sizing, but it is not the defining point of determining a boiler’s efficiency. As referenced previously, boiler efficiency is dictated by the hot water return temperature since the amount of condensation that occurs in the heat exchanger depends on the temperature of the water compared to the flue gas temperature. Hot water supply temperature will almost always be above the condensing point of the flue gases, whereas the return water is the fluid that comes in first contact with the flue gases, cooling them to below the flue gas dew point, causing condensing and recovery of the latent heat from the moisture in the flue gas, which creates the efficiency gains.

Figure 3: The hot water return temperature to a condensing boiler dictates boiler efficiency as the water is the first contact point with the flue gases and more condensation occurs with lower water temperatures.

MYTH #7 – CONDENSING BOILERS ARE MORE DIFFICULT TO SERVICE AND REQUIRE MORE FREQUENT SERVICE

Condensing boilers do not require any more service or maintenance compared to a standard boiler and heat exchanger. A condensing boiler consists of a stainless steel or aluminum heat exchanger that provides more resistance to changing water temperatures as compared to a standard, non-condensing boiler, where the operating temperatures, especially the return water temperature, are extremely important. In theory, although it is not recommended, less care could be provided to a condensing boiler due to its overall robustness. Due to its construction, a condensing boiler will last longer than a non-condensing boiler. If proper water chemistry and maintenance is performed, some condensing boilers are built to last longer than a non-condensing boiler.

Source: Cleaver-Brooks

Written by David Grassl, PE Mechanical Engineer, Principal, Dynamic Consulting Engineers